Search

The Renewable Energy site for Do-It-Yourselfers

$2K Solar

Space + Water: Building the Collector

| This section covers the detailed instructions for building the

collector for the solar space and water heating system.

The collector is built right onto the house south wall. When

installed this way, the wall provides support and stiffness for

the collector, so less material is needed and there and some cost

saving compared to a fully boxed collector. The collector box is

basically just a perimeter frame mounted to the house wall. Using

this arrangement, the collector can be as large as you have wall

for. I think this design also looks better than freestanding

collectors.

This is fifth solar water heating collector I've built, and for

each new generation, I've tried to improve the design over the

previous collectors. I expect that this collector will have a

long life and perform comparably to a good commercial collect (at

about 1/5 th the price).

Back to Table of Contents...

|

|

Overview

The two pictures below give an overview of the collector internals and a

view of the completed collector.

|

Collector box and absorber plate -- ready for glazing.

|

Finished collector with twinwall glazing installed.

|

The collector is built right onto the south wall of the house with a

layer of high temperature insulation separating the collector absorber

plate from the siding. The absorber plate is made with half inch copper

riser tubes joined to 3/4 inch upper and lower copper manifolds. Water

enters the lower right corner of the collector and exits the upper left

corner. The absorber plate fins are made from sheet aluminum formed to

fit tightly over the copper risers.

The glazing is UV treated twinwall polycarbonate. The glazing is

supported by the perimeter frame, and by intermediate vertical and

horizontal metal supports.

This collector is a drain back design, so when the pump stops all the

water in the collector drains back down and out the supply pipe in the

lower right corner and into the storage tank, which is located in the

crawl space below and behind the collector.

On this page:

Absorber Plate Construction...

Preparing the absorber fins...

Making the copper pipe grid...

Installing the absorber fins...

Making the collector frame...

Installing the absorber plate...

Installing the glazing and cap strips...

Absorber Plate Construction

| The collector absorber plate's job is to

convert the incoming solar radiation energy into heat and to

transfer this heat into the water being circulated through the

collector.

For this absorber, fins made from 0.018 thick sheet aluminum

which have been painted black are used to absorb the solar

radiation and convert it to heat. The heat is transferred along

the fin to the nearest copper riser pipe, and then into the

circulating water.

|

This is what we are building in this section.

|

Preparing the Absorber Fins

The fins I used for this collector were purchased pre-formed from Tom

Sullivan at the UP

Truck Center in Upper Michigan. Tom worked out a good efficient

tool for making fins when he was doing

his own collectors, and decided to add the fins to the products he

offers from his UP Truck Center. I believe that this is a good option, as

the fins are made from the right thickness of aluminum, come with a very

well formed groove, and are reasonably priced. But, making

your own fins from locally obtained aluminum is also a good

option. I made my own fins for all the collectors before this one, and

can say that you can turn out good quality fins with simple tools. So,

I'd have a look at both options -- price them out in dollars and your

time, and see what comes out the best for you.

The fins for this collector are made from 0.018 thick aluminum, and the

finished width (after forming the groove) is just over 6 inches. This is

about the right

combination of thickness and width. If the fins are made wider than

6 inches, then the fin thickness should be increase accordingly to allow

for the greater heat flow to each riser pipe. Likewise, if the fins are

made narrower, they can be made thinner without sacrificing efficiency.

Clean the Fins

The fins come as bare aluminum, and have to be cleaned and then

finished.

The side of the fin that faces the sun gets black paint to absorb

the solar radiation well. The back side that fits over the copper

pipe gets a coat of corrosion resistant primer to provide part of

the protection that prevents galvanic corrosion between the

aluminum fin and the copper pipe.

I washed the fins in water with some detergent. Be sure to brush

the inside of the groove so that the primer will adhere well.

I rinsed the fins with a garden hose, and then left the fins to

dry in the sun.

If you make your own fins from aluminum soffit material (as I

have on the collectors before this one), they come pre-painted and

you can forgo the cleaning and priming step (below). If you use

bare aluminum to make your fins, then you do want to do the

cleaning and priming.

|

|

|

Prime the Fins

I used this Rust-Oleum aluminum primer to prime the back side of

the fins. Pay particular attention to getting the primer to coat

the full inside surface of the grooves.

A Zinc-Chromate primer would probably be an even better choice,

but these have become more difficult to come by due to

environmental concerns. The primer I used was available at the

local hardware.

The combination of the primer plus the silicone discussed below

serve to prevent the entry of water into the fin to copper tube

joint area. This prevents any tendency for

galvanic corrosion.

Once the fins are all cleaned and primed on the back side, set

them aside for later.

|

|

Making the Copper Grid

|

The copper pipe grid is made with half

inch copper pipe risers soldered to 3/4 inch copper header

(manifold) pipes. I used the regular Type M copper pipes intended

for residential plumbing jobs.

For the joint between the risers and the

manifolds, I used standard reducing Tees. This is a nice straight

forward way to make the connection, and requires only simple

soldering skills.

The reducing Tees can be quite expensive

depending on where you buy them, but I found that PEXSupply.com has a nice

price on them in quantities of 25.

Be VERY careful to order the type with

3/4 inch on the straight through part, and 1/2 inch on the branch

-- the pictures on the PEX Supply web page are make it easy to

order the wrong ones -- I ended up calling them up to make sure,

and was glad I did as I had picked the wrong version.

There are alternatives to using the

reducing T's -- for example, Ken

worked out a very nice T-Puller...

|

This is what we are making in this section. |

Laying Out the Copper Grid

First, establish the overall size of your

collector. The things to bear in mind when setting the overall size:

-

The wall (or other) space you have

available.

-

Allow for drain back slope: the bottom of

the collector must be high enough to allow for the collector supply

pipe to slope downward from the collector toward the storage tank at

about 3/16thsinch per foot so that the collector drains back to the

tank when the pump shuts down.

-

Efficient use of materials is a

consideration -- try to choose the size to avoid a lot of waste.

-

I For wall mounted collectors, its important

evaluate the roof overhang and make sure that not too much of the

collector will be shaded when the sun is high in the summer. These overhang shadow tools

will help you do this...

-

See the System

Design Section for more on performance vs size of collector ...

All of the above will allow you to establish

outside dimensions of your collector frame.

Now, establish the height and width available

inside the collector frame by subtracting the thickness of the perimeter

frame. The copper grid must then fit inside this space with some

allowance for clearance and for the tilt of the copper grid for drain

back. Layout a rectangle on the shop floor that is the size of the inside

of your collector frame.

Figure out where the supply line is going to

come into the collector. This must be either the left or right lower

corner. The lower manifold will be sloped down toward this corner so that

the collector will drain fully when the pump is turned off.

The return line from the collector must then

connect to the opposite upper corner (that is, if the supply comes into

the lower right, the return must leave from the upper left).

Take the pipe you plan to use for the lower

manifold, and place it in the proper position on your floor layout. This

lower manifold must be sloped by about 3/16ths inch per foot of width

toward the corner where the supply pipe comes into the collector for

drainage. The lowest part of the manifold should clear the collector

frame by about an inch -- this will be at the corner that the supply pipe

comes in. If the manifold is (say) 12 ft long, then the supply end of the

manifold will be about 1 inch above the lower collector frame board, and

the far end of the lower manifold will be (12)*(3/16 Inch) + 1 inch = 3.25

inches above the inside of the frame. Allowing enough slope for good

drain back of the water in the collector is critical for freeze protection

in drain back collectors.

Now layout the top manifold in the same way.

For our 12 ft wide example, the manifold will have about 1 inch clearance

to the top frame on one end, and 3.25 inches clearance on the other end.

It will be parallel to the bottom manifold so that all of the risers can

be cut to exactly the same length.

Now lay in the left and right end riser pipes.

They should be perpendicular to the manifolds, and approximately 3 inches

in from the left and right frame edges. Note that because the manifolds

are tilted with respect to the frame, the riser pipes will be tilted with

respect to the frame sides. Now take a few of your fins, and lay them out

left to right across the full width of the collector. The left most fin

and right most fins should have their grooves centered over your left and

right risers. If the spacing does not come out to an even number of fins,

then you can move the end riser a little to make things come out even. If

you end up moving the end risers out a bit to get an integral number of

fins to fit, then the two end fins can be trimmed with tin snips to fit in

the available space. This does not have to be exact -- if there ends up

being a slight overlap of the fins on each other, or a slight gap between

fins, that's OK -- but, if its more than an 1/8 inch, I'd do some more

fussing around.

Now that you have everything laid out to fit on

the floor, measure the length of the risers, and the length of the short

pieces of manifold pipe that will go between the reducing T's. Be sure to

allow for the length provided by the fittings themselves. Its best to do

a trail cut of a riser, and a couple of the manifold short pieces, and do

a trial fit over your floor layout to make sure you have the lengths

right.

The description above makes this all sound more

complicated than it is. Just start laying it all out on the floor, and

you will quickly see where its going. The most important thing is to make

sure that the collector grid of pipes has down slope so that it will drain

properly, and that it all fits inside the collector frame.

Cut the Riser and Manifold Pieces

Cut out all the risers for the collector -- they will all be the

same length.

There are several ways to make all these cuts.

If you have a regular wood working cutoff saw, I find that works

fine for cutting all the risers at once.

One thing to be careful of is don't count on the nominal 10 ft

pipe lengths to be exactly 10 ft. The 10 ft pipe lengths I bought

varied by as much as half an inch from each other. Basically this

means that if you want a bunch of 9 ft lengths, its NOT safe to

set up a stop to cut 1 ft off your 10 ft lengths!

You can also use an electric saber saw, or one of the cutter

wheel type copper pipe cutting tools that plumbers use.

Now, cut out the short pieces of the manifold pipes. I used my

wood working cut off saw with a stop set to the right length to do

the cutting -- this is fast and assures that all of the pieces

will be the same length.

|

|

|

Soldering the Grid

I think that I counted about 130 solder joints

in the whole grid, so its important to have a good system both to speed up

the work and to avoid leaky joints.

The most important thing to remember is to clean

and flux each joint carefully. If the joints are cleaned and fluxed

well, the actual soldering is easy, and the likelihood of a leaker is

small.

Clean all the fittings

Clean all of the pipe ends and the T fittings carefully. I use

the wire brush tools, but sand paper can also be used.

There are lots of fittings to clean, so mounting the brush to the

drill saves some time for the half inch pipes and fittings -- it

was a bit too much torque for the 3/4 fittings.

Do all the pipes and fittings for one manifold, and then solder

all of those connections, then move on to the other manifold.

This way the fittings don't sit around a long time after cleaning.

|

Cleaning the inside of the T's with wire brush |

|

Terminating the Open Ends of the Manifold

The supply line from the pump will come

into the bottom manifold at one corner. The return line from the

collector leaves the top manifold of the collector at the opposite

corner from where the supply comes in.

This diagonal arrangement between the

supply and return lines insures that the total flow path through

each riser is the same, and that helps to make sure each riser

gets the same amount of flow.

There will be two manifold ends don't

get either a supply or return line. For these corners, its best

to use one of the reducing Tees and terminate the unused branch

with a cap or plug. If you use a reducing elbow to go from the

3/4 inch manifold directly to the last half inch riser, that riser

will get more flow than the others because it has less flow

resistance. Keep the dead end short, as it could be an ice

accumulator.

|

|

Flux all the Joints

Apply soldering flux to all of the cleaned fittings and pipe

ends.

Don't miss any!

|

|

Solder the Joints

Now push all the joints firmly together, and solder each joint.

If you have not done any soldering before, not to worry. There

are lots of good "how to solder" videos that are only a Google

away. Practice on a scrap to get the feel.

After the solder joints cool, wipe them off with a wet rag to

remove the corrosive flux leftovers.

If you did the cleaning and fluxing carefully, you will probably

end up with no leaking joints -- but, be sure to do the leak test

below.

I used ordinary plumbers solder. If you have a choice of solder

melting temperatures, I would pick the highest melting point

solder of the ordinary solders -- probably not worth it to go to

an exotic high melting point solder.

After finishing the first manifold joints, repeat for the other

manifold.

Be sure you solder every single joint -- its surprising how easy

it is to just completely miss soldering a joint -- these tend to

leak :)

|

|

Leak Test

At this point, you want to test for leaks. Its tempting to skip

this leak test, but don't -- its much easier to fix a leak now

than after you have the grid mounted in the collector frame.

To do the leak test, I just plug the return line, then stand the

collector up on its side with the supply connection up. I then

use a funnel and a bucket of water to fill the whole grid with

water -- be sure to get the air out. Then let it set for an hour

or so and look for leaks and make sure the water level has not

gone down. If you have an easy way to pressurize the collector

for the leak test, so much the better.

Its very important to catch any leaks now. Even very small leaks

can cause subtle flow problems later. Sometimes small leaks will

suck in air, and this can cause the pump to loose prime or cause

uneven flow to the risers -- these things are a pain to find and

fix after the absorber is installed, so be sure to do a good leak

test. A test that actually pressurizes the absorber grid is

better than the simple test I show here.

|

Picture of a previous collector being leak tested |

Installing the Heat

Absorbing Fins on the Copper Grid

From a performance point of view, this is

probably the most important step in building the collector -- securing the

fin to the riser tube in a way that will perform well thermally for 50

years.

Install Backing Strip

Place a 3 inch wide strip of 0.018 thick aluminum under the riser

pipe where the next fin is to be installed.

Put a bead of silicone along each side of the fin as shown in the

picture.

An alternative to using the

backing strip...

|

|

Press the Fin Onto the Riser

Press the fin onto the riser pipe with the 3 inch flat strip

under the riser.

Firm down pressure with your palms is all that is needed.

|

|

Clamp the Fin to the Riser Pipe

Clamp the fin very tightly around the riser pipe. When you look

at the fin from the end, you should see no gap between the fin and

the riser pipe.

The picture shows

Tom's modified vice grip clamps, which work very well. But,

you can make

simple clamps that will also do the job... But, either way

its important to have a means to tightly clamp the fin to the

riser pipes.

Once the fins are tightly clamped in place, use short sheet metal

screws to secure the fins to the backing sheet. Use the screws in

pairs directly across from each other as shown in the picture.

The backing plate provided a tension tie across the bottom of the

fin to keep it tightly camped in place.

Some have suggested that pop rivets would work instead of the

screws, and I'd guess that this is true.

|

|

|

You should end up with an absorber grid that looks something like this.

Nearly finished absorber grid. |

showing the fin, riser, strip under riser

and the screws that hold the fin to the

flat strip. |

You can either paint it it black now, or wait

until after its installed in the collector frame.

I built the absorber plate in two halves to make

it easier to handle and move and get out of the shop.

I use the Rust Oleum high temperature barbeque

paint in the flat finish in spray cans. I've used this paint on a number

of collectors with no problems.

After painting, its important to place the

absorber plate in the sun and allow it to bake for a day before putting

the glazing on -- this make sure that all the volatiles are baked out, and

will not coat the back of your glazing.

Making the Collector Frame

| This section details making

the collector frame.

In this case, the collector frame is mounted right to the house

south wall. This allows the south wall to be used for support and

saves some material. I also like the look better than separate

collectors.

Mounting the collector vertically has some impacts on

performance, and you should read over the section on collector

sizing to understand the performance issues. Be particularly

careful if you have a deep roof overhang, which can cause

excessive shading.

The frame is very simple -- basically just a wood perimeter frame

made from 2 by lumber.

|

This is what we making in this section |

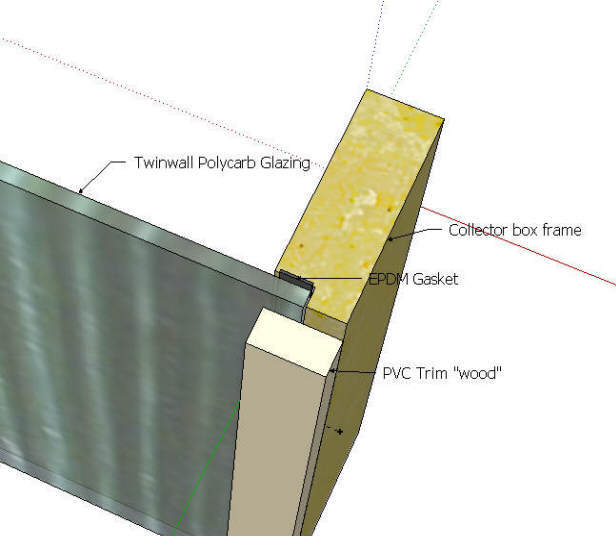

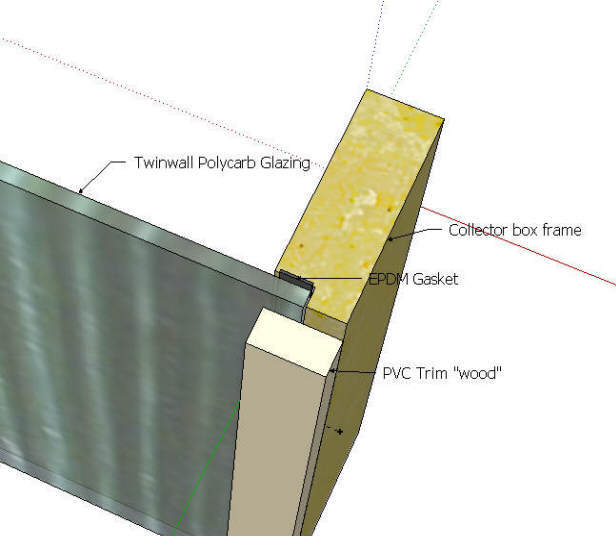

Collector box side frame, glazing, gasket, and cap strip.

Cut the Side Frames

The collector frame is made from ordinary 2 by 6 lumber. Pick

through the pile at the lumber yard and get some good ones --

straight and relatively free of knots and defects.

Cut the two side frames to length. In my case, the side frames

run from just above ground level right up to the eave soffit.

Rip the side frames to a width of 5 inches.

If you don't have a table saw to rip these boards to width, see

the alternative below.

|

|

Scribe the Side Frames to the Siding

I scribed and cut the side frames to match the beveled siding on

the house. To do this, prop the side frame into position against

the wall, and scribe a line onto the frame using the siding as a

guide.

Then cut the scribed line using an electric saber saw.

This scribing operation is not really necessary for most siding

(including mine) -- the idea was to make it look a little neater,

but some careful use of caulking would probably work about as

well.

|

|

|

Groove the Side Frames for the Glazing

The side frames have a groove or rabbet to accept the

polycarbonate glazing.

The groove can be made easily on the table saw by setting the

fence and blade depth appropriately and running the frame through

once for each side of the groove.

I made the groove about 3/4 inch wide, and just over 3/8 inch

thick to accept the 10 mm twinwall glazing.

If you don't have a table saw, see the Simple

Tools version note below.

|

|

Cut the top and Bottom Frame Members

Cut the top and bottom frame members to match the width inside

the two side frame members as shown in the picture.

Rip the of the upper and lower frame members to width such that

they are flush with the bottom of the glazing groove in the side

frame members, this will be about 4 and 5/8 ths inches, but may

vary a bit depending on your siding.

This is a good time to prime and paint the frame carefully. Use

two coats of high quality exterior paint.

If you don't have a table saw, see the Simple

Tools version note below.

Note that the top of this collector is protected from the

weather by being tucked up under the eave. If the top sill of the

collector was exposed to the weather, I would have used a

top sill similar to this collector...

|

|

|

Install the Frame on the Wall

Start by propping the left side frame member up against the wall

in the correct position. Use a level to make sure its plumb.

I used long screws (called log screws locally) to secure the

frame to the house. The screws need to be long enough to go into

the sheathing under the siding.

Once the frame member is in position, drill a pilot hole through

the frame and siding. Then using around a 5/8 spade bit, drill a

countersink hole so that the screw head will be below the surface.

Drive the screws in until the frame is solidly attached to the

wall. With a few screws, this make a very solid mount.

Now install the top and bottom frame members in the same way,

making sure they are level.

Then using the top and bottom frame members as a guide, install

the right side frame member.

|

Driving a screw in for first frame member |

Countersink hole for final frame member. |

Install the Insulation Board

The insulation board isolates the siding and house wall from the

collector.

Use polyisocyanurate rigid insulation board. If you use the

blue, pink or white polystyrene insulation board it will melt --

trust me on this. The polyiso is a little harder to find, but

most lumber yards have it -- it often has reflective aluminum face

sheets.

The polyiso insulation board shown in the pictures is Atlas

R-Board.

Cut the insulation board to size, and secure it with screws. Use

washers under the screw heads to spread the load to a larger area

of the weak insulation board.

|

Placing the insulation board |

Screws with washer. |

Caulk the Frame

Caulk all the edges where frame meets the siding to keep the

weather out.

You should end up with something like the picture to the right.

.

|

Ready for the absorber and glazing |

Install the Absorber Plate in the Frame

| This section details

installing the absorber plate into the collector frame.

The key thing on the installation of the absorber plate is to

make sure that it is installed with adequate down slope toward the

supply line so that it drains completely when the pump shuts off

for freeze protection.

The down slope is accomplished by slightly clocking the whole

absorber plate assembly so that the manifolds slope down toward

the supply pipe corner.

You will want to look ahead to the plumbing section, and figure

out where your supply and return lines are coming in. You may

have to do some of this supply and return plumbing before you

place the absorber plate in the collector.

The absorber plate is mounted on blocks that support it, but also

allow it to move around a bit as it expands and contracts.

|

|

Join the Sections of the Absorber Plate Together

If you built the absorber plate in sections for easier handling,

place the sections in the collector frame.

Using a regular solder coupling, clean, flux and solder the

couplings together.

A clamp is helpful for pulling the sections together, but don't

overdo.

If you think that for some reason you may want to be able to

remove each section at a later time, you could use solder unions

here, but the regular couplings seem fine to me.

|

|

Joining the two sections with a soldered coupling |

Paint

the Absorber

If you have not already painted the absorber, do so now.

I used Rust Oleum high temperature barbeque paint. I've used

this on several collectors and it appears to work well.

Lately I've tried the alternative of having the paint department

at Home Depot mix up a gallon of black flat exterior latex paint.

This appears to work well, and has the advantages that is cheaper

and it does not stink. But, I've not had a collector like this

operating long enough to know how it holds up -- I'm thinking it

will probably be fine. If you are painting bare metal fins, it

may be necessary to prime them before painting with the latex

paint?

Spray painting with a paint sprayer would be another good option

for a large absorber plate.

After the paint is on, be sure to let it cure in full sun for a

day. You don't want to apply the glazing until the paint is fully

cured. Else, it may deposit volatiles on the back or your new

glazing.

|

|

Install the Lower Support Blocks

The absorber plate is supported by a series of support blocks

below the lower manifold. The height of the blocks increases as

you go from the supply pipe end of the collector to the opposite

end -- it is this increase in height that provides the drain back

slope. The slope should be about 3/16 ths inch per foot of

manifold width.

The manifold is clamped to the blocks with copper strapping. The

strapping keeps the manifold in place, but is loose enough to

allow expansion and contraction.

The top manifold is held in place by some ordinary large copper

pipe clamps. These do not support the manifold, but just keep it

from tipping outward. The full weight of the absorber plate is

supported by the blocks under the lower manifold.

The absorber grid is supported in this way so that it can expand

and contract as it heats and cools without overstressing it.

|

Support blocks along bottom of collector |

Close-up of the support block and clamp strap |

Collector Glazing and Cap Strips

| This section covers

installing the glazing supports and the glazing.

This collector is glazed with three sheets of 10 mm thick

twinwall polycarbonate glazing.

Vertical supports must be added to support the vertical edges of

the twinwall panels. Lightweight horizontal supports are also

used to control the tendency of the panels to bow inward as they

are heated.

To hold the twinwall panels in place, cap strips made from

plastic wood are used.

|

This section covers installing the glazing. |

Install the Intermediate Vertical Supports

The outer edges of the outside panels sit in the grooves in the

collector frame, and the top and bottom of all the panels sit

directly on the collector frame top and bottom sills. But, two

additional vertical supports are needed to support the middle

panel vertical edges and the outside panel inside vertical edges.

I used two square steel extruded sections with a 1.25 outer

dimension. The wall thickness is about 0.1 inch. I used these

steel sections because they are straight, strong, and fit in the

limited space in front of the absorber (I wanted the absorber to

be continuous across the full collector).

The vertical steel glazing supports are secured to a block of

wood that is in turn screwed and glued to the collector box

sills. This allows easy removal if the absorber ever has to come

out. Alternately (probably better) would be to make these blocks

from the cutoffs from the steel glazing support tubes.

The steel sections get a couple coats of Rust Oleum enamel.

This is the first time I've used this kind of glazing supports,

and I'm quite happy with the results. The collector glazing is

well supported and stays flat as a pancake.

|

|

|

Install the Horizontal Glazing Supports

Lightweight horizontal glazing supports are added at about the

1/3rd points in the twinwall panels. These supports control the

tendency of the twinwall to bow inward as the collector heats up.

I use thin wall EMT electrical conduit, which is straight, cheap,

readily available and galvanized for rust protection.

The inner end of the EMT is supported by drilling a hole through

1.25 inch square steel extrusion to accept a length of threaded

rod. The nuts are installed on the threaded rod, and the EMT is

just a tight friction fit over the nuts. See the picture to the

right.

The outer edges of the EMT is simply installed a small notch cut

in the collector wood frame and secured by a screw.

I place a thin bead of silicone caulk along the front face of the

EMT to cushion contact with the twinwall.

I used these EMT supports on the Solar Shed collector, and they

have been working fine for more than 5 seasons with no sign of

problems.

|

Threaded rod and nuts that support the

glazing support tubes. |

Middle attachment of horz glazing support |

Outside end attachment of horz glazing support |

Install the EPDM Gaskets

I used EPDM rubber gaskets to between the glazing supports and

the twinwall panels.

The EPDM was just strips cut from scraps of the EPDM tank liner

(see the tank section).

To hold the EPDM in place, I used a bead of silicone caulk on the

glazing supports, and just pushed the EPDM into it (picture).

I used the EPDM gaskets along all of the glazing supports (top

and bottom sills, edge frames, and steel supports), but not on the

EMT horizontal supports.

The twinwall panels are just pushed into the EPDM strips by the

cap strips -- no adhesive is used to hold the glazing in place --

so, its each to take out if need be.

In the past, I've just mounted the twinwall directly onto the

wood glazing supports using cap strips, and this worked fine, but

I thought the EPDM would give a little better a seal and a little

more flexible a mount.

.

|

|

Install the Glazing and Cap Strips

The first step in installing the glazing is to seal off the top

and bottom of the twinwall panels with aluminum tape (pic to

right).

Tear of the inner protective plastic wrap on the twinwall panel.

Make sure that the side that has the UV protection faces out --

just follow the "this side out" label.

Next, clamp the left twinwall panel on the supports. Make

certain that the right vertical edge is properly aligned on the

steel support. There should be a small gap between the panels

where they meet on the steel support (about 1/8 inch). Once

everything is lined up, install the cap strip over the left edge

of the panel to hold the panel in place. This is where you will

find out how good a job of plumbing the steel supports you did :)

I used the PVC "wood" that is sold for house trim instead of real

wood. My experience is that wood cap strips have a short life.

I attached the cap strips with stainless steel wood screws on the

outer edges.

To attach the cap strips to the steel supports, I bought 1/4 inch

stainless bolts, and installed them in holes that I threaded for

the bolts in the steel supports.

The cap strips should be snugged into place, but not overly

tightened.

The top and bottom cap strips are installed in the same way.

I know that some twinwall glazing instructions talk about

allowing for the panels to expand and contract and that there are

some fancy mounting systems that are supposed to accommodate this

movement by allowing the panels to slide. Feel free to try them,

but 1) I am skeptical that they really allow the panels to slide,

and 2) based on 5 seasons of experience on the Solar Shed project,

they do not appear to be necessary.

|

|

|

|

|

Alternatives

Quite a few people have done collectors using this basic design, and

several of them have provided descriptions

of their collectors. Have a look at

these alternatives to see if any of the details fit your needs better.

Simple Tools

You don't need a table saw or any fancy tools to build this collector.

You can use a standard 2 by 6 for both the collector frame sides and top

and bottom sills. Just eliminate the groove in the 2 by 6 for the glazing

and mount it right on the top surface of the 2 by 6. This way the sills

and the side frames are the same depth, and the glazing can sit right on

the 2 by 6.

I would carry the glazing out nearly to the outer edge of the 2 by 6 in

order to provide good support for the plastic wood trim board.

The small gap at the edge of the glazing can be sealed with a couple

small, neat beads of caulk of a color that matches the frame.

A vertical section through one of the side frames (or a section through

one of the sills, since it would look exactly the same).

Metal Trim

Metal Frame

Another possibility is to build the collector frame from metal.

Ken shows one way to do this using galvanized metal track as is used in

building construction...

We are happy with the final look.

Gary February 9, 2011