Search

The Renewable Energy site for Do-It-Yourselfers

Ken's DIY Solar

Air Heating Collector -- Aluminum Soffit Absorber

| This is Ken's homemade solar air heating collector. The

collector uses high quality, long life parts in a high efficiency

design.

Thanks very much to Ken for sending this

in!! |

|

Overview

This is my homemade solar hot air

collector. If you are looking for a super cheap collector this is not for you.

But if you are looking for a lower cost, easy to build, long lasting collector

that you will be proud of, this might be what you are looking for.

Features of this collector:

-

No wood is used in the

collector.

-

This collector is a matrix

absorber collector.

-

Vented aluminum vented

soffit is used for the absorber matrix.

-

The glazing is twin-wall

polycarbonate.

-

The frame is made from

metal stud track.

Materials and Cost

Material list and prices as of

10/10/10:

-

1-4x8 sheet of 6mm twin wall

polycarbonate $40

(bought at Menards)

-

2-4x8 sheets of 1

polyisocyanurate insulation $27

(the yellow stuff with foil)

-

2-16x12" full vent aluminum

soffit or 4-half vent $30

-

3-5 ½ inch stud track 10long $? (an alterative is 2 PVC 6x6 post cut length wise

)

-

1-can of primer and 1-can of

color paint for frame $10

-

1-can of flat black barbeque

grill paint $5

-

1- Thermal snap switch $15 (a

thermostat that turns the fan on and off)

-

1- 6duct fan $30

(an alterative is a used furnace vent fan)

-

Short metal screws and 8 screws

with rubber washers

For a total of around $200.

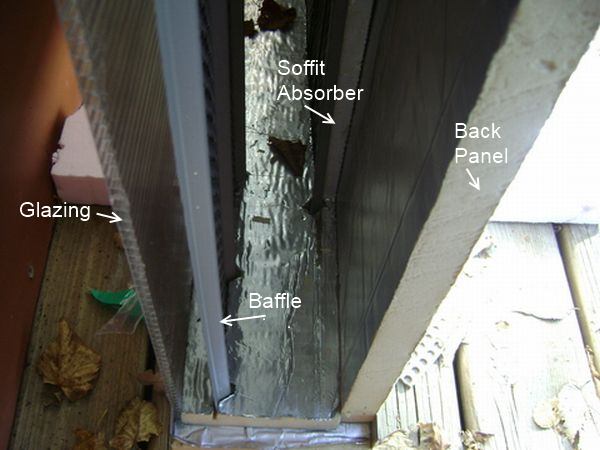

How it Works

| Sun shines on the aluminum soffit absorber material,

heating it up.

Cool room air enters the collector inlet, which is near

the bottom and on the back of the collector.

A baffle placed just behind the glazing then deflects the incoming air to the

sides and prevents the air from impinging directly on the glazing.

The air flows up and through the vented soffit absorber plate

striping the heat off the soffit.

The air (now hot) flows up behind the soffit and out the outlet at

the top back of the collector and into the room. |

|

Building the Collector

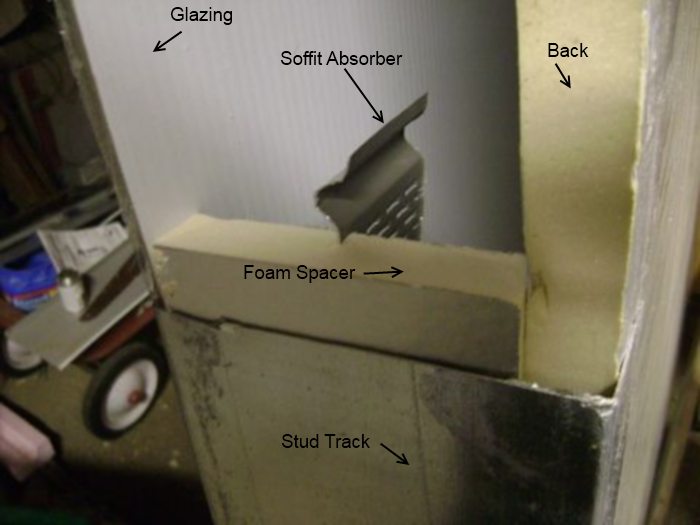

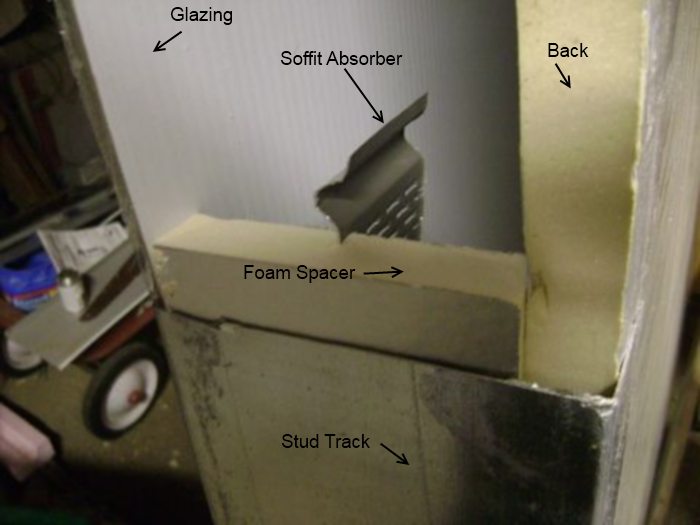

The collector is a sandwich of the

glazing, a foam spacer that holds the soffit, and the back insulation held to

gather with the stud track.

The picture above is a cutaway of the

collector sandwich:

- The glazing (front of the

collector) on the left (has the white cover plastic on it)

- The foam spacer with the soffit (inserted ½ into it) in the center

- The insulation panel on the right

- The stud track holding it all together

This picture shows the aluminum

vented soffit material that is used to make the collector absorber.

The half vented soffit is on the

right.

A piece of the stud track that is

used to make the outer frame for the collector is shown on the left.

If you can find it, its best to use the fully vented soffit, but if you cant

find the full vent soffit you will have to cut the non-vented part of the soffit

off with a tin snips.

| |

Note: Home Depot can special

order fully vented soffit from Amerimax Home Products, as shown in

this collector..., but you have to order a full box. |

I was not able to get the fully

vented soffit, and cut off the non-vented parts off of the half vented sheets.

The half vented soffit with the non-vented part cut off is in the middle of the

picture above.

Cut the soffit to a width 1narrower then the glazing width

(48-1=47).

Now paint the soffit black on the

side that will face the glazing.

Then lay the soffit panels out so

that they form a finished absorber panel that is 47 wide by about 7 less

than 8 tall. The number of strips of soffit material needed to make the

full height will vary depending on the soffit material. The 8 open area

will be at the bottom of the collector so that you can install the air intake.

Use three screws per joint to fasten the soffit pieces together to make the

absorber panel.

The

stud track makes up the frame of the collector. If the track has a extra

long legs you will want to put a piece of insulation in the stud rail to make

the remainder of leg a little over 1 ( on mine I user ¾ insulation).

Cut the vertical (sides of the collector) stud track the length of the glazing +

twice the leg spacer insulation. On mine it was 8 1 1/2 long.

The top cap piece of stud track is

cut the width of the glazing + twice the leg spacer insulation + twice the

height of the stud track leg length and a little to fit over the side pieces. So

on mine it is 48 +(3/4x2) 1 ½ +(2x2) 4=53 ½+ ¼ inch.

The bottom inside piece is the same 53 ½ but ¼ inch.

I hope that not to confusing.

Now cut a slot in the ends of the cap stud track and the bottom stud track

so the end can be folder over. The cuts should be cut from the end on the leg of

the track so that when folded over the corner of the stud track will cover the

corner of the fold.

Stud track with the

cut from the end on the legs next to the corner. The sides have been folded in.

Bending the top

down

Inside after

bending.

Paint the four pieces of stud track the color of your

choosing. I've heard that if you wash galvanized steel with vinegar

before painting the paint will stick better.

Outside of the

cap. The top corners over lap the seam.

Now make the the

insulation spacer pieces.

The four pieces will

be cut to a width so that it will fit snugly inside the stud rail between the

glazing and the back insulation. (refer to the second picture). The 2 side

pieces will be the length of the glazing (96 - 2 = 94 inches). The

top and bottom spacers will be the same width as as the glazing (48

inches).

Next cut a ½ inch deep groove for the soffit in each spacer. Cutting this

groove with a power saw works well.

At the same time cut

the slots for to accept the baffle. The baffle slots will be a ½

from the glazing and on the bottom of the side pieces.

The groove for the

absorber plate (soffit) will be at a angle going a ½ from the glazing on the

top of the collector to the back of the collector near the bottom you will have

to measure the absorber panel to get the length from the bottom (about 10? )

You will want the bottom of the absorber to be tight to the back insulation

panel.

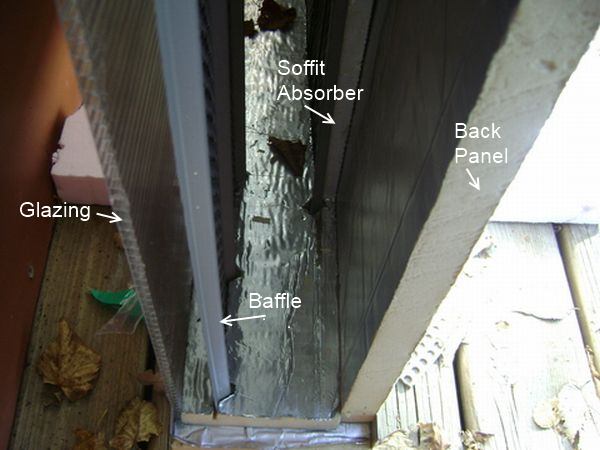

Looking from the

glazing side with the collector on its side.

The absorber (soffit) and baffle have been inserted into the slots in the side

insulation.

Looking into the bottom of the collector with the stud track on the side.

From the left you have the glazing, baffle, absorber, and the back insulation.

With all the parts ready you can insert the baffle and the absorber panel into

one of the side insulation pieces then put the other side insulation on the

other end of the baffle and absorber panel. Put the glazing on front side and

the back insulation on the back side and work the side stud rail over the

sandwich. Hold together and flip over and work the other side stud rail on. Now

you can put the top insulation in place and put the top cap on. Then put the

bottom insulation in place and put the bottom stud rail between the side stud

rails.

Now you will put 2 screws into each of the 4 corners to hold the collector together.

All you have left to do is mount the collector and cut the holes for the intake

the outlet holes.

All done -- looks

great!

Questions?

Kenneth participates in the

Yahoo Solar Heat discussion group, so that's a good way to ask questions --

if you post your question on the discussion group, everyone will learn from the

question and answer.

If you want to email Kenneth, you can get him at:

Gary January 15,

2011