Search

The Renewable Energy site for Do-It-Yourselfers

Measuring Collector Performance

and Efficiency (roughly)

|

Here are some simple methods to measure the

heat output of your solar collector, and to make a rough estimate of collector

efficiency. AND, some common misconceptions in collector design.

Directory for this page:

|

|

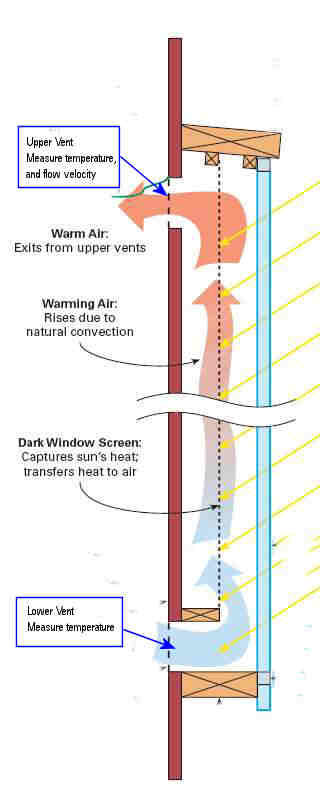

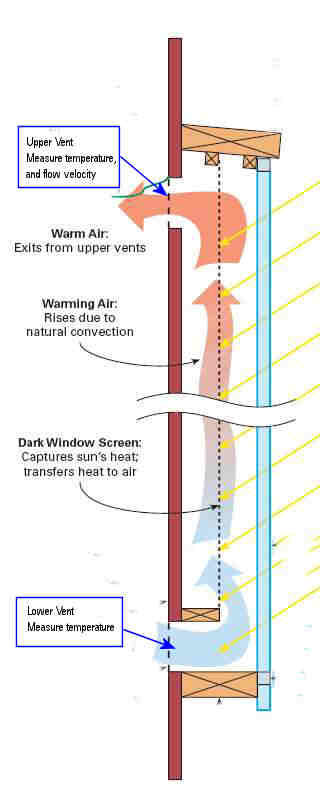

Measuring Heat Output from a Solar Air Collector

You can determine the heat output of

your collector by measuring just two things:

The Heat Output is directly

proportional to the product of these two quantities. Any collector

design change that increases this product increases the heat output of the

collector.

The actual heat output is:

Qout =

(Weight Flow of Air)*(Toutlet - Tinlet)*(Cair)

where Cair is the specific heat of air (i.e. the amount of heat needed to

raise 1 lb of air 1 deg F)

Since its hard to measure weight

flow, we can substitute the (volume flow of air) (air density) for the Weight

Flow of Air. And, the Volume Flow is just the (Velocity of Air) (Outlet

Duct Area).

So, the heat output becomes:

Qout = (Vair)*(Aduct)*(Dair)*(Toutlet

- Tinlet)*(Cair)

Where:

Vair = average air velocity out

the outlet duct (ft/min)

Aduct = the total area of the

outlet duct(s) (ft^2)

Dair = density of air

(lb/ft^3)

Toutlet = average temperature of

the air exiting the outlet duct (deg F)

Tinlet = aaverage temperature of

the air entering the inlet duct (deg F)

Cair = specific heat of air

(BTU/lb-F)

Dair is 0.075 lb/ft^3 at sea level

and 60F, but the air density decreases as it is heated, so for normal collector

temperatures, 0.065 lb/ft^3 is pretty good.

Cair is 0.24 BTU/lb-F

Doing the Measurement:

Pick a time and day with the sun

conditions you want. Usually this would be a clear day around

solar

noon.

Measure the inlet and outlet

temperatures:

Secure one thermometer in the inlet

duct and one in the outlet duct (e.g. tape them in place). Make sure the

bulb or active part of the sensor is near the middle of the flow. Make

sure the sensor is not getting direct sunlight on it -- you may have to

improvise a shade. Make sure the temperature sensor does not impede the air flow to

any significant degree. Any of the temperature sensors listed

here will work -- a couple of dime

store thermometers will work fine.

Measure the average air flow at the

outlet vent:

Measure the air flow

velocity at the outlet duct. If the duct is large, measure the velocity

in several places and average.

Pick a velocity measuring device

from one of these that matches the flow

velocities and conditions you have. You may also be able to measure the

flow by timing how long it takes to fill up a large plastic garbage bag of

known size.

If you are getting a lot of

fluctuation in the velocity reading, try taking ten readings at fixed intervals (e.g.

every 5 seconds) and average them.

This velocity should really be

corrected for the fact that velocities near the duct edges are slower than the

center, but you may be willing to forgo this bit of accuracy (I usually do).

Repeat these measurements at least 3

times. For example, do one set at 5 minutes before noon, a 2nd at noon,

and a 3rd 5 minutes after noon. Throw away any readings that are widely

different from the others. Average the rest.

So, as an example, suppose for your

collector you measure:

Aduct = 1.5 sqft

-- the area of the outlet vent or duct

Toutlet = 120F

-- the average air temperature of the outlet air

Tinlet = 65F

-- the average air temperature of the inlet air

Vair = 110 ft/min

-- the average velocity of the air in the outlet vent or duct

Then, the collector output would be:

Qout = (Vair)*(Aduct)*(Dair)*(Toutlet

- Tinlet)*(Cair)

Qout = (110ft/min)(1.5 ft^2)(0.065

lb/ft^3)(120F - 65F) (0.24 BTU/lb-F)

Qout = 141.6 BTU/min, or

8,494 BTU/hr

If you think that the greater the

temperature rise through the collector, the more heat output the collector is

producing, you should read "Collector Misconceptions" below.

If you make a change to the absorber,

and the outlet temperature drops to 105F, but the velocity increases to 130

ft/min, was this a good change or a bad one?

Water Collectors

The heat output for water collectors

is done in much the same way as air collectors:

Qout = (Weight

Flow of Water)*(Toutlet - Tinlet)*(Cwater)

The only things that have changed

from the air collector equation are that now you measure the water flow (instead of airflow), and you use the

specific heat of water (instead of the specific heat of air).

If you measure the flow rate of the

water through the collector in gallons per minute, then the equation becomes:

Qout = (Flow Rate gallons/min)*(8.2

lb/gallon)*(Toutlet - Tinlet)*(1.0 BTU/lb-F)

So, if you have tested a water

collector, and measured the following:

Flow Rate = 1.2 gpm

Tinlet = 80F

Toutlet = 100F

Then the heat output is:

Qout = (Flow Rate gallons/min)*(8.2

lb/gallon)*(Toutlet - Tinlet)*(1.0 BTU/lb-F)

Qout = (1.2 gallons/min)*(8.2

lb/gallon)* (100F - 80F)*(1.0 BTU/lb-F)

Qout = 197 BUT/min or

11,800 BTU/hr

The best way to measure the flow

through the collector is to divert the collector flow into a container of known

size, and time how long it takes to fill -- this method is accurate and cheap.

If the simple approach is not workable, than a flow meter can be used to measure

the flow. Taking water flow measurements is

discussed here.

Estimating Collector Efficiency

Accurately determining collector

efficiency is a difficult proposition that requires some fairly expensive

equipment to do well. I will describe a method below that will allow very

rough estimates of collector efficiency to be made with just the measurements

you made in determining heat output above, plus a table lookup for the solar

radiation on the collector. But,

bear in mind that this is a rough estimate.

A little background on collector

efficiency:

The plot below shows the efficiency

curves for three types of collectors. The vertical axis shows

efficiency. The horizontal axis shows difference between the average

collector temperature and the ambient air temperature. It is clear

that efficiency is not a constant -- it depends strongly on the temperature

difference between the collector and the outside air. As you would expect, the collectors

all show better efficiency when there is not much difference between the

collector temperature and ambient (because the collector losses are greater when

its colder out).

Collector efficiency chart -- these

are for 3 sample collectors from the SRCC site.

All data are for a solar radiation

level of 254 BTU/sqft-hr (800 watts/m^2)

The plot shows efficiency curves for three types of

collectors are shown:

Unglazed Collector:

The low-tech unglazed (pool type) collector has the best efficiency of all the

collectors when the temperature difference between collector and ambient is

small. This is because it has no glazing, and therefore none of the

incoming sunlight is absorbed or reflected by the glazing -- all of the sun

gets to the absorber. As temperature difference between ambient and

collector increases, the performance of the unglazed collector falls off

rapidly, because there is no glazing to reduce losses from the

absorber to the outside air.

Evacuated Tube Collector:

The evacuated tube has the highest efficiency of the three collectors when the

temperature difference between collector and ambient is high. This is

mainly because the vacuum in the tubes is excellent insulation and reduces

heat loss due to conduction and convection to very low levels. The

absorbers also have a selective coating that reduces radiation losses.

But, when the temperature difference between collector and ambient is low to

moderate, the

evacuated tubes have the lowest efficiency -- not sure why this is?

more absorption in the curved glazing? (Note -- it appears that the

low efficiency of evacuated tubes at low delta temperatures is due to

the fact that the SRCC uses the full area of the collector array when

calculating performance, and the evacuated tube arrays have lots of open space

that do not collect. This brings down their efficiency. If you

calculate efficiency based on absorber area, the evacuated tubes are near 80%

at the intercept. But, it seems to me that the SRCC is correct in basing

the efficiency on the actual size of the array -- that's how much roof space it

takes up).

Flat Plate Collector:

The performance of the glazed flat plate collector is better than the

evacuated tube at low temperature and better than the unglazed at high

temperatures. This curve is

for a collector with a selective coating on the absorber.

Understanding the performance

differences between these collectors, and the underlying reasons for these

differences will allow you to make a better estimate of how your collector will

behave, and allow you to make design changes that will improve its performance.

The SRCC and the SPF provide performance test data for many commercial

collectors. It is interesting to look at the designs, and the efficiency

curves, and see if you can spot why they perform the way they do.

Collector performance test results.

Its important to look at the whole efficiency curve, and in

particular, the portion of the curve where your collectors are going to be

operating. Some collector

manufacturers quote the efficiency of their panels for low or zero values of Tcollector - Tambient

-- except for pool collectors, this is a worthless number, since you will almost

never use the collector under this condition.

The other form of collector

efficiency curve you may see changes the parameter along the horizontal axis by

dividing the temperature difference by the incident solar radiation. The

parameter is:

Horizontal Axis Parameter = (Tcollector

- Tambient) / Isolar

Where Isolar is the solar intensity

on the collector in BTU/sqft-hr or watts/m^2

This change allows a single curve to

characterize collector performance for all sun levels, rather than having a

separate curve for each solar radiation level.

To get a rough idea of the

efficiency of your collector:

You need two things:

- The heat output of the collector,

as estimated in the section above.

- The solar input corrected for the

angle of incidence.

The efficiency is then calculated

as:

Efficiency = (Collector Heat

Output) / ( (Collector Area) (Solar Intensity) (Cosine(Incidence Angle)))

If you have an instrument that is

capable of measuring the solar intensity ,

then you can measure the solar intensity, and you are all set -- just plug it

into the formula above.

Unfortunately, these tend to be pretty pricey instruments, and most of us won't

have one.

Another way to get the solar

intensity is to look up the value for for

the location, date and time that you did the test, and use this. This is

approximate, in that atmospheric conditions on the day of the test will effect

the solar radiation level. Here is a

procedure:

Pick a day that is very clear and

sunny (you can only look up sun intensities for clear skies)

If possible, do the test near

solar noon, when the

sun is due south.

If possible, tilt the collector

panel so that the sun is shining directly onto it (so the solar rays are

perpendicular to the front face of the collector) -- this makes the table

lookup for solar radiation easier, and gives more consistent results. If

you can't orient the panel, then its probably best to do the test at the hour

where the collector azimuth is directly at the sun. For example, if the

panel is aimed 15 degrees east of south, do the test at 11am solar time (the

sun moves 15 degrees of azimuth per hour).

Determine the collectors heat

output. The procedure for doing is is covered in the first part of this

write-up.

Look up the solar intensity for the

location and date of the test -- here are two ways to do that:

Look it up in a table:

You can use the tables here to look

up the solar radiation on your collector. The tables give the

radiation per sqft of of collector, so you must multiply the number you read

from the table by the collector area. Find the table page that most

closely matches your latitude. Then find the table date that most

closely matches your test date. Then find the orientation in the table

that most closely matches your panel orientation. If you did the test

at solar noon with the panel pointed directly at the sun, then read the

value from the table for noon, and for the tilt of your panel (this should

be the highest radiation value for that day). If you did the test at

another time of day, or panel orientation, then pick the best matching

radiation number from the table.

Use the Radiation On Collector

Program: Another way to get the solar intensity is to use my

Radiation On Collector

program. You will need to download it, run it, and enter the date and

orientation of your collector. Also enter the area of the collector.

From the output, pick out the total radiation (last column) at noon.

The program accounts for incidence angle and collector area, so no

corrections are needed for these.

The approximate efficiency of your

panel is then:

Efficiency = (Heat Output) /

(Solar Radiation on Panel)

Where:

Heat Output is the value you

measured in BTU/hr (or watts)

Solar Radiation is the value

you looked up in the table, or got from the program.

For example: you have a 20

sqft panel that is mounted on a vertical wall that faces south. You measure a heat output of 2600 BTU/hr. You

conduct the test on Nov 15, and your latitude is 41 degrees.

Table Method: The closest

table entry is for 40 deg latitude and Nov 21 -- use it. Read the number

from the table for a vertically mounted panel at solar noon. You

should get 258 BTU/sqft-hr.

So, multiplying by panel area, the total radiation on the collector

is:

Total Radiation on collector = (258 BTU/sqft-hr)*(20 sqft)

= (258)(20) = 5160 BTU/hr

And, the efficiency is:

Efficiency = (Heat Output) / (Solar Input)

= (2600 BTU/hr) / (5160BTU/hr) = 0.50 or 50%

Radiation On Collector Program

Method: Using the radiation on collector program, enter the

date of 11/15, tilt of 90 degrees (vertical), Azimuth of 0 deg (due south),

collector area of 20 sqft, latitude of 41 deg.

Running the program for

"Calculate Day" you will get this output.

You can read the total radiation

on the collector already corrected for incidence angle in the last column at

noon of 5121 BTU/hr.

So, the efficiency is:

Efficiency = (Heat Output) / (Solar Input)

= (2600 BTU/hr) / (5121 BTU/hr) = 0.51 or 51%

So, as expected, the two methods

give pretty much the same answer.

You now have a rough estimate for one

point on the efficiency curve. You can get an idea how well your panel

does compared by commercial ones, by using the SRCC or SPF efficiency curve for

a panel that is similar in construction to yours, and plot your estimated

efficiency point on it. If you fall way below the curve for the similar

panel, its time to start scratching your head about your design.

Some of the factors that make this a

very rough estimate:

The measurement of of heat output

has inaccuracies in the temperature and air velocity measurements.

The actual sun intensity will

differ from the value looked up in the book due to the atmospheric conditions

on the day of the test. I believe that these variations can be fairly

large.

Ground reflections (particularly

from snow) increase the radiation on the collector, and are not accounted for.

If you have a snow field in front of a vertical collector, the snow reflection

can add 30% or more to the incident radiation.

So, be very careful and humble about how you use

this efficiency estimate.

Collector Design Misconceptions:

These are my 2 cents on some of the

things that people tend to get wrong in collector design, and some of the things

that are most important in a successful collector. If you don't agree, I'd like to hear about it.

That Efficiency is the be all/end

all of solar collectors:

Efficiency in solar collectors is

important, and should not be ignored -- you should always try and verify that

your collector is performing in the same efficiency range as proven collectors

of the same type.

But, that said, most people are more

interested in how much economic return they get on the money they invest in a

collector. So, the real figure of merit for a collector should be

something like :

Economic Return = (dollars

saved per year on energy) / (cost of the collector).

Most decently designed collectors do

not vary widely in efficiency, but collectors do vary widely in cost, so

maximizing economic return is usually more about building collectors for less money

than it is about squeezing the last bit of efficiency out.

Collector AREA is king:

The most important collector design

parameter is COLLECTOR AREA. You can work very hard, and spend a lot

of money improving the efficiency by 10%, but its not going to get you anything

remotely close to the effect of doubling or tripling the collector area.

This is one of the beauties of DIY collectors -- you can build a DIY collector

for $5 per sqft that performs just about as well as a commercial collector that

costs $25+ per sqft -- so use that advantage to double or triple or quadruple the

area! If you have the space -- build big. A corollary to this is

that its not a lot more work to build a 4 ft by 10 ft than it is to build a

2ft by 3ft collector -- build the larger one.

High Output Temperatures Don't Mean High

Efficiency:

Sometimes people think that the hotter

the outlet temperature on a collector the more efficient it is, and the more

heat it is producing. This is usually NOT true. In almost all cases cases

collectors will be more efficient operating at relatively high flow rates, and

at relatively low collector temperature rise. The reason for this is that the

higher the collector temperature, the more heat will be lost out the glazing --

heat lost out the glazing reduces the heat output of the collector. So,

generally you want to try to set the flow rate such that the temperature rise is

the lowest that will work for what you want the hot air for. For

thermosyphon collectors, you want the path through the collector and absorber to

be as free flowing as possible -- this will give you higher flow velocities and

lower temperature rises, and a more efficient collector. For thermosyphon

collectors, this means choosing an absorber material that has both good

absorption AND low flow resistance.

If this does not make sense to you,

just remember that its the product of the temperature rise times the flow

velocity that determines the heat output. If you make a change that

increases the temperature rise by 10%, but in doing so you decrease the flow

velocity by 20%, you have lowered the heat output of the collector.

You can also directly see the effect

of high collector temperatures by examining the efficiency plot above. When the

temperature rise through the flat plate collector is 50F, the efficiency is

nearly 60%, but when the temperature rise is increased to 100F, the efficiency

drops to about 40%.

Adding Thermal Mass to a Collector

Improves Performance:

I don't know where this comes from,

but a lot of people seem to feel that adding mass to a collector will improve

its performance. It is better to keep the mass down, so that the

collector comes up to temperature faster when the sun comes up or comes back out

from behind a cloud. You want an absorber that absorbs well, and you want

sufficient flow through the collector to pick up the heat from the absorber

without undue rise in the collector temperature, but thermal mass is not

required for this. If your system needs thermal mass for storage, the

worst place to put it would be in the collector, which has very high losses to

the sky once the sun goes down.

Gary

2/13/2006