Search

The Renewable Energy site for Do-It-Yourselfers

Solar Water

Heating Using a Unique Master and Slave Collector Design

Gordon describes his new solar water heating system. It is

loosely based on our

$1K solar water

heating system, but includes some really interesting and helpful

innovations including:

- A unique "Khanh" collector design that utilizes a large slave

collector to improve the performance of a smaller master collector.

- A new tank design that makes use of a

galvanized stock tank lined with EPDM, well insulated, and low

profile.

- A very nice and compact multi-coil

copper heat exchanger.

- Some techniques for improving drain

back on systems with marginal drainage slope.

Gordon shows a great deal of ingenuity in

working out a way to install a water heating system that works well and

looks good into a very difficult situation.

Thanks very much to Gordon for sharing

this!! |

|

Update 3/30/2013: Two Year Update from Gordy

A very complete update after 2 years of service covering: performance, pumps, plumbing updates,

the backup heater, the new differential controller, and more...

Adding Solar Water Heating:

In a prior ‘schoolhouse

retrofit’ article, we mentioned an intention to eventually construct a solar

domestic hot water heater. The project is now essentially completed and we are

happy to describe the difficulties we faced, the choices made and the resulting

preliminary performance.

Being essentially out of sight and out of mind, the typical water heater seems

often to be taken for granted. However, the energy consumption of a water heater

is really quite significant. By undertaking the deep energy retrofit, we thought

we had made a fairly major effort to reduce our energy footprint. Since then,

Ontario has introduced time of use smart metering and stiff increases in

electricity pricing. As a result of the retrofit, our electricity consumption

was down considerably – but the monthly billings remained relatively constant.

Even though we had lowered the thermostat on the electric water heater to about

115 degrees F., installed a mechanical timer (restricting powering the water

heater to night-time use), and primarily powering the heater with 115V rather

than 230V (¼ power) - the water heater still consumed nearly 3000 kWh per year!

Of our total electric consumption, about 60% was a result of the water heater!

Drooling with envy regarding Gary Reysa’s

$ 1000 solar heater

described on his “Build-It-Solar” web site, we decided that we too, would make

the plunge.

Gary’s drainback system involves a water storage tank open (essentially) to the

air, a small pump is used to lift the water to the top of the collector, and

gravity is used to return the warmed water to the tank. If the collector is no

longer warmer than the tank, the pump is deactivated and the water drains out of

the collector – providing cold weather freeze protection even in cold climates.

Ideally the solar water storage tank is located close to a normal hot water

heater and cold water is routed through a coil in the solar storage tank to

preheat the water prior to entry into the normal hot water heater. For added

performance, Gary has sized the coil, so that under most situations, the heat

exchanger operates at maximum efficiency.

We are of the opinion that simplicity and ruggedness are the key features of an

elegant design. Gary’s concept of a solar drainback system composed of

inexpensive, easily obtained common parts is a classic. We approached the

project knowing that we couldn’t improve upon his design – but could we achieve

near equal performance in view of the tough constraints of our situation?

Tough Constraints:

The house is located in a relatively

cold climate that experiences considerable rain and snow, and sometimes, high

winds. Winter to summer temperature differentials are significant and result in

major thermal expansion/contraction of roofing. One is advised to avoid complex

roof designs and roof penetrations if possible. Placing a collector on the roof

is just not advisable.

The cold water pressure system and hot water tank were located near a north wall

in the utility room – a great distance from any feasible collector locations.

There was no space available in the utility room for a solar storage tank. The

closest feasible location was an adjacent room – but this would involve about 68

feet of inter-connecting PEX and the resulting substantial heat losses.

There were only two feasible locations to locate the collector – and both

involved serious concerns. The two possibilities were actually adjacent

one-another on the southerly wall of the house, one facing due south and the

other 30 degrees east of south. Unfortunately for the location facing due south,

the garage shaded the location by mid-afternoon during the wintertime.

Unfortunately for the east of south location, mature trees shaded the location

in early morning, particularly in early summer. Both locations involved a

distance of about 65 feet from the only potential location for a water storage

tank – that’s a least 130 feet of PEX tubing and involves serious heat losses. A

separate solar collector/garden shed was possible, but would involve

considerably more piping and heat loss.

Click on pictures for full size.

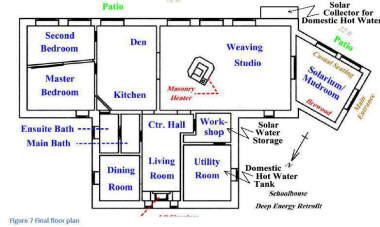

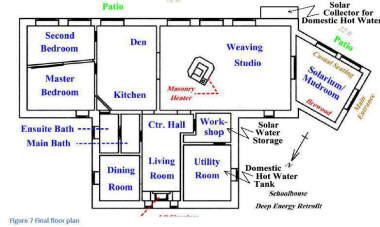

The new solar water heating collector

just to the right of the new sunspace. |

The layout of the converted schoolhouse

showing the collector and tank location.

|

Being an old schoolhouse, there is neither basement nor crawl space to locate

the storage tank. A roof location for the collector was not acceptable.

Together, this meant the tank would have to sit on the main floor and the

collector would have to be mounted to the wall. This would restrict the gravity

return to being from the bottom of the collector to the water level at the top

of the storage tank – a very small vertical distance over a very long horizontal

distance.

The gravity return must completely empty the collector to avoid freeze damage.

Piping between the outside wall insulation and the collectors must be well

insulated and provided with considerable slope to ensure that the static water

level would be well inside the wall (in the heated house). This suggested that

the static water level had to be at least 12 inches lower than the bottom corner

of the collector manifold.

To minimize heat loss, a cubic (or better still a spherical) water storage tank

is preferable. In our case, the height of the water level was severely

constrained, so we had to consider a very low, long tank design. This would

involve a much greater total surface area, much more insulation, and more

thermal heat loss than usual.

There were very few routing opportunities for the PEX tubing between the

collector and storage tank. One could go up across the unheated attic – but

gravity drainage of the collector could not be achieved. One could construct an

exterior insulated trench around the house – but we would be intercepting at

least a dozen electrical, water and drainage pipes along the way. Anticipating a

possible use, during the renovation we had threaded a 4 inch “Big O” (and pull

rope) through an original concrete sub-slab heating duct. One end was near the

potential collector location, the other, relatively close to the preferred tank

location. Both ends would involve some breaking-up of the concrete floor.

Bundle of 5 half inch diameter PEX

tubes being fed into the

under slab "Big-O" duct. |

Uncoiling the PEX during

the under slab pull. |

The PEX bundle pulled into

the storage tank area. |

This 4 inch “Big O” actually involved several relatively tight corners. Ideally,

two heavily insulated 1 inch PEX lines out to the collector would be desirable.

Such was out of the question! We would have to make do with four ½” PEX lines

and no insulation (two out, two return). Actually, we used five ½” PEX lines

(the fifth used for a sensor wiring chase and spare should damage occur to one

of the others). The five lines were wrapped and taped with landscape cloth to

protect the PEX. The PEX bundle was pulled in one difficult ‘go’. We got it

inches from where we wanted it, took a minute’s breather, but it would never

budge from there again! We made do. The heat loss from this pipe run would be

bad – but there didn’t seem to be a feasible alternative. As this route was

under the slab, another implication surfaced - it would never actually drain.

In summary, the constraints of our situation were truly abysmal. This would be a

hell of a test for a drainback solar hot water system. If it were to prove to be

feasible in our situation, it should be much easier for just about everyone

else!

The Collector:

When undertaking the preliminary

research for our passive solar and deep energy retrofit, we collected together

and read several dozen books on the topic. Many were old and out of print. Most

people would consider this effort a waste of time, as so many of the efforts of

the ‘60s and ’70 had serious shortcomings. I was surprised to realize that many

of the early concepts are valid, more so now, than when proposed - now that we

have substantial improvements in various building materials. One book I truly

fancied was “New

Inventions in Low-Cost Solar Heating – 100 Daring Schemes Tries and Untried”

by Professor William A. Shurcliff, Brick House Publishing, 1979, ISBN:

0-931790-02-6. It’s a great book to get one out from under the suffocating cloak

of conventional thinking.

On pages 118-125 of this book, Dr. Shurcliff describes a concept invented in the

early ‘70s by Dr. Dinh Khanh of Gainesville, Florida. The elegance and

simplicity of his concept is riveting. In a nut-shell, he suggests that, as

active solar collectors are rather expensive to purchase or build (on per square

foot basis), why not make best use of such collectors by substantially improving

their efficiency and/or reducing their thermal losses! His proposal is simply

the construction of a much larger, but inexpensive, passive air collector

(slave) over the active (primary) collector – putting the active collector in a

‘hot house’! More technically, the inexpensive slave collector provides a warm

environment around the expensive primary collector – so that it has far lower

thermal loss to the outside, and thus performs at a much higher temperature than

would normally have occurred. The concept is simple, yet open to many ways of

actually doing so.

The problem we faced with our collector was that the location limited us to a

nine foot width. The height was limited by the eaves trough down pipe and

effects of snow accumulation. The bottom was severely constrained by the

requirement of gravity drainage to the other side of the dwelling. The allowable

collector area was smaller than desirable for a system operating under ideal

conditions - and our situation wasn’t even remotely similar to ideal conditions.

Due to the thermal losses of several hundred feet of PEX, we needed a collector

much larger than normal, perhaps double in size – but it was just not possible!

We had no information as to whether

anyone had ever successfully tried Dr. Khanh’s idea, but we decided to attempt a

variant of the concept.

The collector is two 4ft wide units,

side-to-side, about 10 ½ ft tall, steeply tilted to the side of the house. As

the storage tank sits on the interior floor, the requirement for gravity return

flow restricted copper risers to the upper 2/3s of the collector – the primary

collector. The basic construction is conventional - ½” copper risers on 5”

centres, ½” copper manifolds top and bottom, and black painted, hand formed

aluminum fins screwed and silicone glued to a plywood base panel. The lower 1/3

of the two collectors is a ‘slave’ - simply black painted aluminum screwed to

the plywood base panel. Behind the plywood bas is a layer of fiberglass ceiling

panels (for high temperature insulation), then a 1 inch thickness of foil faced

urethane.

Side view of collector.

The gutter and gutter drain constrain

the height of the collector. |

The fiberglass ceiling tiles being placed

over the foil faced urethane insulation board. |

The variant of the Khanh concept we

decided to construct involved a single glazed ‘slave’ physically below a double

glazed active collector (‘primary’). Hot air generated in the lower slave

convects up between the one inch gap between the glazing layers on the front of

the active collector. A slot in the top of each module and a wooden baffle

conveys this warm air stream to the rear of the active collector.

|

The lower slots for air circulation in

the slave collector. |

The upper slots for air circulation in

the slave collector. |

The two modules are supported by five 2 by 4 studs leaning against the house. 1

½” XPS foam insulation was glued and screwed to the rear of these studs across

the back of the modules. This insulation, in conjunction with the 2 by 4s and

insulated plywood base of the collectors, creates four vertical air channels

down the back side of the collectors. Each of the four air channels has a

cross-section of about 1 1/2” by 21”. The air heated by the slave collector gets

conveyed down these channels and routed back to the slave at the bottom.

In summary, the air warmed in the slave is repeatedly reheated and recycled

around both the front and back of the conventional copper tube/aluminum fin

collector. Thus the conductive and convective thermal losses normally associated

with such collectors are nearly eliminated.

The copper tube with aluminum fin active

portion of the collector on top. |

The three PV panels are installed

in the slave collector area. |

For the glazing material we chose Palram Suntuf. Two 8 foot lengths for the

inner glazing and two 12 foot lengths cut to 10 ½ feet for the outer glazing.

Hopefully it has the level of UV resistance claimed by the manufacturer. The

vertical corrugations provide stiffness and stability, but additionally seem to

improve light transmission at acute incidence angles.

We had three small PV panels (nominal 15W each) not doing anything useful. They

were mounted in the slave collectors with the hope that they might power the

circulation pump. Actual performance of the PV panels is significantly lower

than the rated output – perhaps 1 ½ to 2 amps at around 17V. Not good enough!

The inner Suntuf glazing panels installed.

Note the vent holes above the PV panels. |

The finished collector with the active section on top and

"slave" collector extending to the ground.

Total size is 8 ft wide by 10 1/2 ft high. |

Thermal Storage Tank:

The storage tank sits on a 2”

thickness of foil faced urethane, laid over 1 ½” of Type IV XPS foam directly on

the original concrete slab. The four sides are insulated with 2” of foil faced

urethane and 3” of XPS. As the tank resides inside the home, the risk of

tank leakage/failure was a major concern. After much thought, we purchased a

galvanized farm stock trough, and then proceeded to coat it with five thin

layers of EPDM paint to further protect it from corrosion. The tank was then

lowered into four layers of poly (standard vapor barrier). The tank was then

lined with an EPDM pond liner like the usual “BIS $1000 drainback” tank design.

A heavy wooden frame of 4 by 4 corners posts and 2 by 6 upper and lower rails

surrounds the stock tank providing support for the side insulation and

conventional foam insulated, plywood top (with pond liner). Hopefully this

configuration will provide a longer life than typically expected of the usual

plywood box arrangement.

Storage tank frame construction. |

Insulating the tank assembly. |

The stock tank installed over

four layers of poly. |

One disadvantage of the stock tank is the rather narrow width. It is too narrow

to consider using 1” or even ¾” coils of PEX as the heat exchanger. We

constructed two 75 foot coils of 3/8” soft copper, configured them in parallel

feeding about 12 feet of 1” copper pipe (folded back and forth). This does not

provide the stored hot water volume we would like, but should provide an

attractive heat exchanger efficiency.

Initial testing with olive barrel. |

Adding rainwater to fill the tank. |

Closing the tank lid. |

Completed copper heat exchanger.

Two 75 ft coils of 3/8 inch ID copper

in parallel. 12 ft of 1 inch copper pipe

used structural frame and water storage. |

Lowering the heat exchanger into the tank. |

Pump Selection:

One of the few advantages of having

the bottom of the collector a short vertical distance from the tank surface is

that it minimizes the vertical head that the pump must accommodate.

Unfortunately, due to the long distances and narrow tube sizes, head loss due to

pipe friction at start-up is substantial. We went through the calculations and

eventually selected a 12V DC

Swiftech

MCP655 (a computer server pump). It has a variable speed capability, but in

our configuration, maximum speed (about 2 ½ amps) provides slightly less than 2

gal/minute – slightly under the ideal flow rate, but certainly adequate. It is

mounted on very generous sized rubber mounts very near the floor, and coupled to

heavy rubber hoses - the pump is very nearly silent.

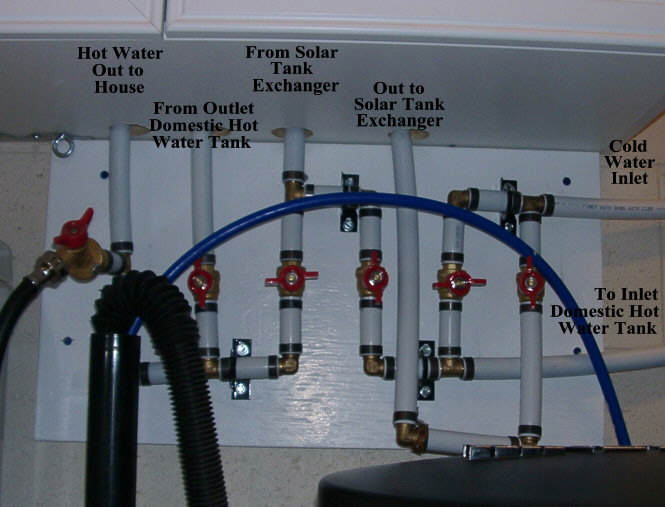

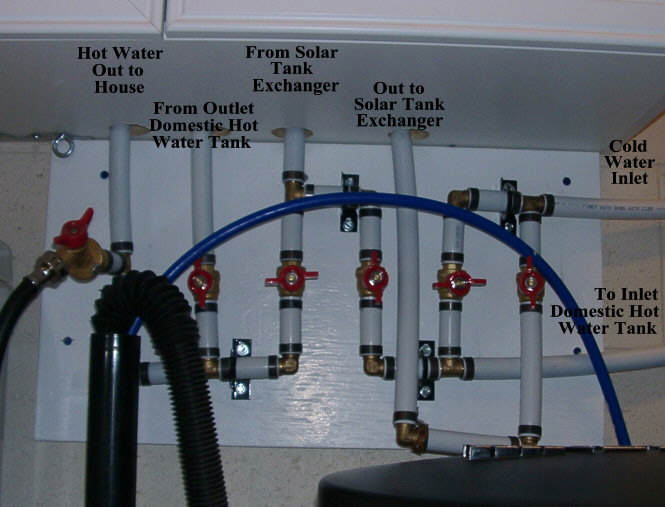

Gate valve choices -- electric heat, or solar heat, or both.

Pump Controller:

I intend to design and construct a

differential temperature controller to properly drive the pump. It has yet to be

decided whether it shall be based upon a BASIC Stamp, an AVR controller or a

conventional comparator circuit.

In the interim, I was hoping that the little PV panels could accomplish a

somewhat similar job. Alas, Murphy was an optimist. This of course was not so.

The PV panels provide perhaps 2/3s of the needed power, but not enough. Trying

to haywire a battery and/or wall wart to power share with the PV panels

presented new frustrating difficulties. For the interim, the PV panels only

trigger an optically isolated, zero crossing, solid state relay, which controls

mains power to a DC power supply (a power adapter for a 13V Koolatron cooler).

Initial Testing:

Murphy was indeed in the drivers

seat. It didn’t work!

When the pump was initially powered up, it just couldn’t raise the water high

enough to get to the top of the collectors. Eventually we realized that there

had been some small bubbles caught in the line - the pump just can’t tolerate

them on the inlet side! Upon purging the line, we were in business. Or were we?

Then we realized that upon stopping the pump, the drainback feature wouldn’t

initiate! In a cold climate that would be deadly! In an attempt to visualize

what was happening at the inlet and outlet of the two collectors we introduced

tees and gate valves (just inside the house) inter-connecting both inlets and

both outlets. Two clear vinyl tubes were connected to see where the water levels

occurred. The lower tube was connected about two feet down from the lower

manifold. The upper tube was connected about mid-way down the copper risers.

Almost by accident we realized that if the valves to the upper tube were left

cracked slightly open, the air break would consistently initiate rapid

drainback. A brief opening of the valve on the lower tube confirmed that the

static water level was confined within the house. During normal pump operation,

the Bernoulli effect at the tees of the cracked open upper valve would draw some

air into the return line but it seemed to have no detrimental effect upon the

gravity return flow. Better yet, even during pump start-up, there didn’t seem to

be a noticeable affect. Just maybe Murphy was on holiday.

Interior view of the collector outlet and the air

bleed valves. |

Interior view of the water level indicator

below the the collector inlets. |

Our initial tests involved a small olive barrel inside the tank, as the tank

assembly had yet to be completed. The results, shown on this link here,

surpassed our expectations. Dr. Khanh’s concept seems to have increased the heat

output by about 50% - yet had involved a very low cost!

Finally the tank was completed To complicate matters, we were using rainwater

for the tank/collector circuit. The rain barrel had frozen solid, so we had to

bring in small buckets of water – when and if, small amounts thawed. Eventually

the tank was filled.

Unfortunately, we hadn’t had a sunny day in weeks! Occasionally we had an

opportunity to test aspects of the control system, but with so little sun, the

tank remained cold for weeks more! Over the period the tank water became very

slimy. We start to worry how that could be controlled. When the copper heat

exchanger coils were finally installed, the slim problem disappeared over-night.

We were relieved!

Preliminary Performance:

The system became fully operational

23 December 2010 – but still no sun! It was not until 4 January 2011 that a full

sunny day occurred. In the previous seven weeks we had the equivalent of only 4

short winter days of sun! We expect to have a fair amount of cloud in November

and December, but this had been extreme I guess the moral is that we experience

weather systems, and weather systems don’t necessarily remember to behave like a

sequence of coin tosses over three to five days.

4 January 2011 was sunny, outside temperature hovered at freezing, and winds

were very light. There having been snow the day before, test conditions were

excellent! Throughout the test, the collector temperature exceeded 111 deg. F.,

peaking at 119 deg. F. Starting at 63 deg. F. at 9:10am, the tank temperature

slowly rose to 101 deg. F. by 2:30pm. Then the pump control shut down. About 98

gallons of water had been raised a temperature of 38 deg. F. That’s equivalent

to 31,600 BTU over 5.33 hours (or about 5930 BTU/hr). The active collector is

52.96 sq. ft, thus the heat output is equivalent to about 600 BTU/sq ft of

active collector per mid-winter day.

Conclusions:

Assuming this winter day’s test is

representative of sunny day production throughout the year, the solar collector

can be expected to produce about 75% of the annual hot water need. If the

initial testing is indicative of somewhat warmer weather performance, this is

likely to be a major underestimate as warm weather production should be

significantly better. A solar portion exceeding 85% annually would not be

surprising.

If Dr. Khanh’s solar collector concept can be adapted to your situation, it

would appear to be well worth the small cost and effort!

No, we weren’t able to construct the system for $ 1000. The cost may well have

been double. It should not really be surprising as the purchasing power of the

U.S. dollar for building materials, far exceeds that of the Canadian dollar.

It’s definitely not a weekend project – more like five months, but not rocket

science. Thanks Gary for the inspiration.

If we can make a high quality, solar hot water heater work in our abysmal

situation – you can too!

Go for it!

Gord & Sue Scale,

Email:

Note: Gordon is logging systems performance and will send in a one year report

after the first year of operation.

9 Jan. 2011

Some thoughts on Gordon's solar water

heating system:

- The use of the Khanh collector

is very interesting. Its the only actual application I know of of this

concept. It will be very interesting to see how the performance works

out -- I'm inclined to think it will result in a significant improvement.

This has got me thinking

about a free standing version of the $1K solar water heater, where the

collectors and tank would be integrated into a small shed like structure

that would sit against the south wall of the house, or nearby the house.

The collectors could use the Khanah design with the active part of the

collector extending from the top of the tank upward, while the slave

collector extends all the way to the ground.

Gordon's comment on

the free standing versions is that if you want solar hot water, but

don't plan to stay in your current house, that this kind of free

standing installation could be mounted on trailer wheels. You

could take it with you when you move!

- Its (maybe) worth noting that

while the plan to solar power the pumps has not been successful yet, the

Swiftnets pump only uses about 24 watts. This gives an COP under good

sun conditions that is over 100!

- Gordon worked out a very

innovative way to insure that his collector drains back when the pump

turns off. I would caution people that if you have a situation that is

marginal for draining back reliably that you put the time into making

absolutely certain that your system does drain back as Gordon did. A

frozen and burst collector can ruin your whole day!

- I share Gordon's enthusiasm for

Dr. Shurcliff's “New Inventions in Low-Cost Solar Heating – 100 Daring

Schemes Tries and Untried” book. Its my all time favorite solar book.

Dr. Shurcliff allowed me to scan the out of print book and make it available

for anyone to read --

its here... great reading for people interested in solar

innovation.

- Note the comment in Gordon's

article about the growth in the tank clearing up when the copper heat

exchanger was added. Maybe introducing some copper into storage tanks,

or using one of the copper based treatments is a good way to avoid any

tendency for growth in the tank? I find in my tanks that as long as

the tank temperature gets up above 140F once in a while that growth is

minimal to none, but the copper may be a good additional measure.

- Gordon used a galvanized metal

stock tank with several coats of a paint on EPDM paint, followed by an EPDM

sheet liner. In addition, several layers of poly film were used

outside the tank as a final protection against leaks. Gordon

wanted all the leak protection he could get because of the tank location.

But, I wonder if for most applications where the tank is located in a less

critical area (like a basement or crawl space), if the galvanized stock tank

plus several coats of the EPDM paint would not be a good way to go? It

would be less labor and would eliminate the cost and somewhat fussy job of

install the EPDM membrane.

Note that galvanized stock tanks also come in round versions, which would

easily accommodate a large coil of PEX style heat exchanger, but the round

tank would be more difficult to seal the lid to as you could not use the

wood sill around the tank for a seal surface.

Gordon notes that the EPDM

paint peformance was not impressive, but there may be better products

out there. Another alternative:

Gary Reif describes his experience with Permaflex...

- For those who have not read

Gordon's article on the conversion of the old schoolhouse into a

super-insulated and very energy efficient home,

its an amazing

story...

Gary

January 24, 2011