Search

The Renewable Energy site for Do-It-Yourselfers

Solar Shed --

Controls and Plumbing

|

The controls for the Solar Shed space

heating system are very simple.

Basically, a standard off the

shelf Goldline GL30 is used to control the pump that circulates fluid

through the collectors.

When the pump is off, the

collectors drain back to the tank for freeze protection.

The pump that circulates hot

tank water through the floor loops is controlled by two thermostats.

The first senses whether the house needs heat, and the 2nd senses

whether the tank has heat. If both of these things are true, the

pump is turned on to circulate hot water through the floor.

Basically the plumbing in the

collector loop is all one inch copper and is all sloped toward the tank

for drain back.

The underground pipe to the

house is CPVC insulated with extruded polystyrene rigid foam

board.

More detail and parts below.

Go back to

the main Solar Shed page ...

|

|

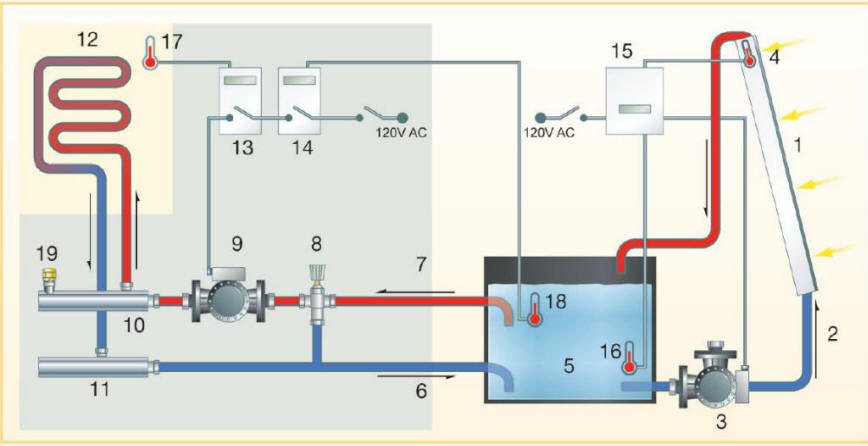

This controls diagram is from the

Mother Earth News article on the system.

The full diagram and labeling are

available

here ...

The full Mother Earth News article on

the system is

available here ...

This is a

more detailed wiring diagram for the pump and controls...

Referring to the controls diagram

above,

For the collector plumbing circuit:

The Goldline GL30 differential

controller reads the temperature of the tank from sensor 16, and reads the

temperature of the collector using sensor 4.

If the collector temperature is

greater than the tank temperature by an amount that you set on the

differential controller, the controller turns on the pump (3).

The pump circulates water through

the collectors (1) as long as the collector temperature remains at least 4F

greater than the tank temperature.

If the collector temperature

drops to less than 4F above the tank temperature, the controller (15) shuts

off the pump (3). The water drains from the collectors back to the

tank -- this keeps water from freezing in the collector and damaging it.

For the circulation through the floor

loops,

For heating, hot water flows from

the tank (5), through the underground pipe (7), through the thermal mixing

valve (8), through the circulation pump (9), and into the supply manifold

10.

From the supply manifold, water

flows out to each of the 6 floor loops of PEX pipe, and then back to the

return manifold (11).

From the return manifold, water

flows back through the underground pipe (6) to the tank.

The function of the thermal

mixing valve (8) is to mix some of the cooler returning water with the

incoming hot water if the temperature of the incoming water is too hot to

circulate through the floor.

The valve is adjustable over a

wide range of temperatures, and prevents the floor from being damaged by

circulating excessively hot water.

Water only circulates through the

floor if 1) the house needs heat, and 2) the tank has water hot enough to

provide heat.

The two thermostats (13 & 14)

turn the pump on only under these conditions.

Thermostat (13) senses the house

temperature, and only turns on when the house temperature falls below the

value you set.

Thermostat (14) senses the tank

water temperature, and only turns on when the tank is above the temperature

you set.

These two thermostats are Johnson

Controls A419s. They will directly control the 120VAC circuit that

powers the pump -- so no low voltage control wiring is required.

Both of the two thermostats are

located together next to the supply and return manifolds.

Thermostat (14) senses the tank temperature via a 150 ft long set of wires

to the temperature sensor located in the tank.

See pictures below.

Plumbing components

15 Goldline

GL30 Differential controller

2

One inch copper pipe between the collector and tank -- sloped toward tank

3

Taco 008 120 VAC bronze circulator pump

16

Temperature sensor -- senses tank temperature for GL30 -- a 10K thermistor

4

Temperature sensor -- senses collector temperature for GL30 -- a 10K

thermistor

5

Tank is an insulated plywood shell lined with EPDM rubber sheet.

6, 7 Insulated

CPVC pipe that runs from the tank to the house.

8

Taco thermal mixing valve

9

Grundfos UPS 15 120VAC circulator pump (probably to be replaced with Taco

008 bronze pump)

10, 11 The supply and return

manifolds. These have connections for up to 6 floor loop circuits in

my case

12

Floor loops of PEX pipe heat the floors when water is circulated through

them

19

Air bleed valve

13, 14 Johnson Controls A419

thermostats to control the pump (9)

18

Temperature sensor that reads the tank temperature for thermostat 14

17

Temperature sensor that reads room temperature for thermostat 13

The manifolds also have valves

and connections for filling the system, and have shutoff valves to shut off

flow between the tank and the manifolds.

The manifolds also have valves

and flow meters that allow the flow in each floor loop to be controlled and

monitored.

I plan to replace the iron

Grundfos pump with a bronze of stainless steel pump -- I used it because it

was on hand. Systems like this that are vented to the atmosphere

should not use iron parts because the air in the system can rust the iron.

The tank collectors and floor

loops all share the same plain water -- no antifreeze.

There are no heat exchangers in

the system.

A heat exchanger may be required

in the floor loop system depending on the elevation of the floor compared to

the elevation of the tank.

Pictures of the Plumbing

Floor Loops:

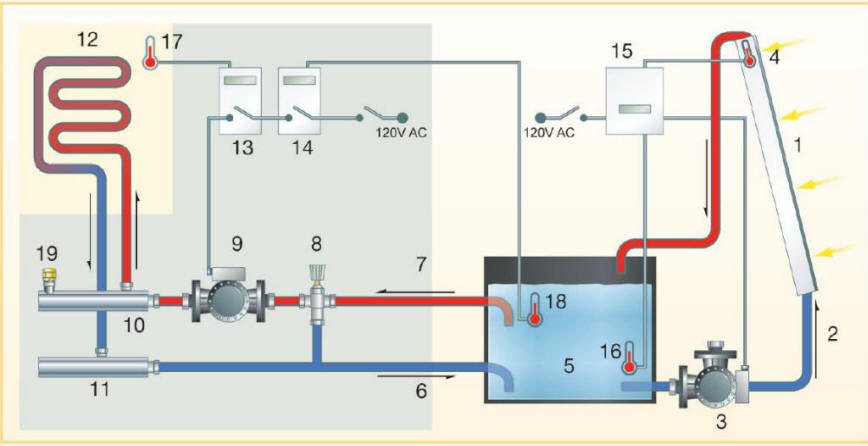

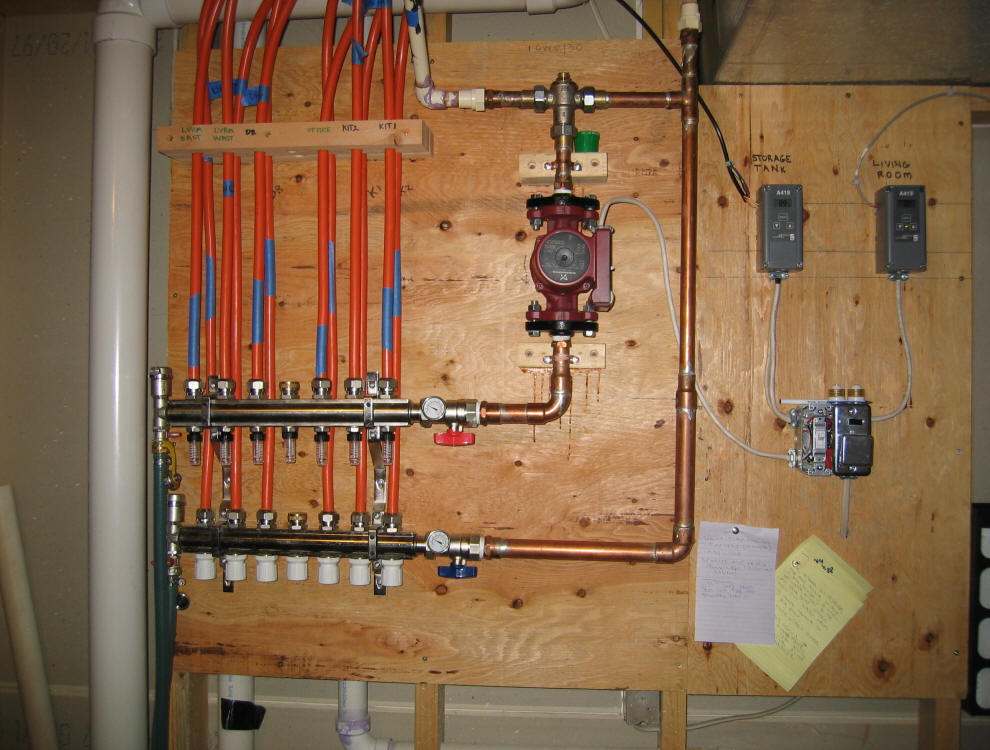

The supply and return manifolds with

the orange PEX pipe running to the 6 floor loops are on the left.

The two Johnson control A419

thermostats that control the system are to the upper right.

The Grundfos pump and Taco thermal

mixing valve (just above the pump) are in the center.

The manifolds were bought as a

package, and include a number of helpful features: fill valves, air bleed valve,

supply and return shut offs, supply and return temperature gages, and individual

flow valves and flow gages for each floor loop -- this makes the system much

easier to fill and troubleshoot.

The fused switch to the right turns

power off to the whole system. The switch right next to it turns the pump

alone off (for troubleshooting mostly).

Picture showing floor loops being

installed.

Plywood spacers are used to make a

groove for the PEX pipe. Homemade aluminum sheet heat spreader

plates are used to improve the heat transfer to the room

This shows the Taco 008 bronze

circulator pump that circulates water to the collectors mounted to the side of

the tank.

The connection through the tank wall

is just below the pump body.

This connection is made through a

bulkhead fitting.

This is the only plumbing line that

penetrates the tank wall -- the rest of the connections go over the top edge.

The tank sits low enough that the

inside of the pump is always flooded -- the pump is not self priming.

The insulation arrangement is set up

to allow the pump to pick up enough heat from the tank to prevent freezing, but

not so much as to overheat the pump.

The pump is rated for continuous

operation at 200+F, so the insulation arrangement is probably not too critical.

This shows the new arrangement of all

of the plumbing connections to the tank except the pump (see above).

All of the connections come in over

the top of the tank through grooves in the boards that surround the top edge of

the tank.

This allows a lid with no connections

through it, so it can be removed easily.

A little messy, but functional.

The connections from left to right

are:

- Return water from collectors --

must terminate above the tank waterline

- Tank vent line -- just runs over a

bit and up a bit -- allows air to enter or leave the air space above the water.

- The tank temperature sensor lives

inside the angled copper pipe -- its a 10K thermistor.

- CPVC line to the house. The T

on the end of this line is set up about 3 inches under the tank water surface --

it conveys hot water tot he house.

- CPVC line coming in from the

right corner is the water return line from the house -- it continues over the

the lower far end of the tank

The white gunk is silicone caulk to

keep water vapor from escaping the tank.

There is a stainless screen filter

cartridge in the CPVC supply line to the house just beyond where it exits.

At the end of the first season there

was nothing in the filter.

The lid for the tank is lined with

EPDM on the bottom, then a couple layers of rigid foam insulation, topped off by

a layer of OSB.

The lid is clamped down to the tank

with long deck screws at about 1 ft intervals. This connection has proved

to be vapor tight.

Gary Dec 1, 2007