Search

The Renewable Energy site for Do-It-Yourselfers

Insulating a Sliding Glass Door

|

This is a small project to cut the

heat loss through our sliding glass door.

The project consists of installing a

one inch thick R-Board rigid insulation board panel just inside of the fixed

panel on the sliding glass door. The new insulation board panel sits

against the Vinyl frame of the sliding glass door, and the allows the sliding

panel slide by it easily. We intend to install this panel in the winter

and remove it in the summer -- it only takes a moment to take the panel in or

out. It cuts the heat loss for the sliding glass door nearly in half, and

saves about $40 of fuel and 200 lbs of greenhouse gas per year.

R-Board is one brand of

polyisocyanurate rigid insulation board made by Atlas. There are a number

of brands of this type of insulation. The R-Board works nicely because it

has a fairly smooth and attractive face sheets that are also fairly durable and

more resistant to fire that the bare insulation (but see warning below).

|

|

Click on images to enlarge

The new insulating panel installed just inside the fixed side of the sliding

glass door. The sliding panel (on the left) slides behind the new

insulation panel. The insulation panel is 1 inch thick

polyisocyanurate edged with wood strips and painted -- it adds about R7 to the

existing windows R2.

Building It

Have a look at the frame on your

slider, and try to find a flat surface that the new insulation panel can seal

against, and still allow the sliding part of the door operate. On ours the

vinyl frame provided this surface nicely.

This

shows how the insulation panel fits against the Vinyl frame of the sliding glass

door. The sliding part of the door (left) slides behind the new insulation

panel. Weather stripping (not yet installed on this picture) seals

the vertical gap between the slider frame and the insulation panel when the

slider is closed.

This

shows how the insulation panel fits against the Vinyl frame of the sliding glass

door. The sliding part of the door (left) slides behind the new insulation

panel. Weather stripping (not yet installed on this picture) seals

the vertical gap between the slider frame and the insulation panel when the

slider is closed.

Once you have decided where panel is

going to go, carefully measure the size of the panel, allowing some clearance to

be able to get the panel in and out easily.

I edged the panel with wood strips to

make the panel more rigid, make it easier to handle without damage, increase the

fire resistance of the edges, and to make it look better. If you are going

to use wood edge strips, then subtract the width of these strips when cutting

out the insulation panel.

Cut the insulation panel out.

It cuts easily with a long blade razor blade knife as shown below. Use a

straight edge to guide the knife, and do the cut in two or 3 passes, cutting a

little deeper on each pass.

After the panel is cut to size, glue

on the wood edge strips.

Apply glue to both the foam board and

the wood strip. The foam board absorbs some glue, so use a fairly liberal

coating. Clamp the edge strips in place, and wipe off any excess glue.

If you don't have the clamps, you can

tack the edge strips in place with 2 inch finish nails, and then turn the panel

on edge and apply a little weight to the top edge until the glue dries.

Or, you could use a contact cement that does not require clamping.

After the glue dries, sand off any

rough edges and give the panel a coat of latex paint.

After the paint has dried, install

the panel in place and secure it. I used 4 dry wall screws that were just

long enough to through the insulation panel, and into the door frame, but not so

long as to interfere with operation of the slider.

While we had intended to install the

panel in the winter, and remove it in the summer, we just left it up for the

summer. The siding glass door works fine with the panel in place,

and it lets in plenty of light with or without the panel. But, its easy to

remove for the summer if you want to.

Warning

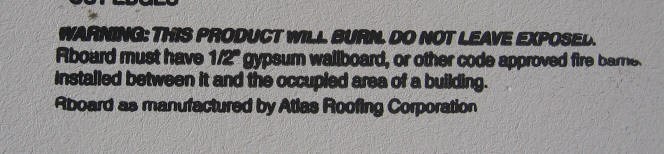

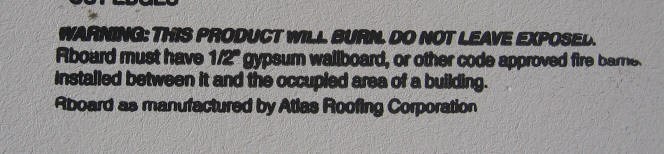

While these insulating panels have

been commonly used to make this kind of interior insulating shutter, be

aware of this fire danger warning printed on the insulation panel:

So, make your own judgment on whether you

want to use this material.

Performance

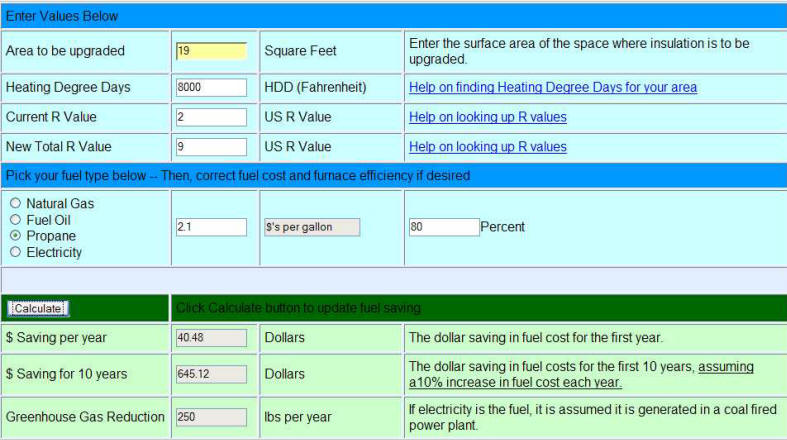

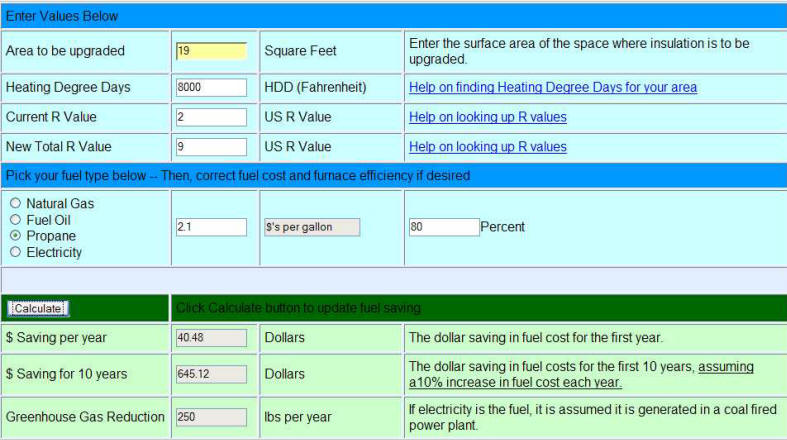

I used the

Insulation

Upgrade Calculator to estimate the saving in heating fuel and in green house

gases.

Inputs for the calculator:

Area = 19 sqft (35 by

78 inches)

Current R value = R2.0

(Double glazed )

New R value = (2 + 6 + 1) = R 9

(2 is existing window, 6 is insulation, 1 is new airfilms)

Heating Degree days = 8000 (a

cold climate)

Fuel = Propane at $2.20 per

gallon

Furnace efficiency = 90%

The first year fuel saving is $40,

and the yearly reduction in CO2 is 250 lbs.

For me, the cost was $19 for the

insulation panel plus some scrap wood -- a payback period of one

half year!

Here is the Insulation Upgrade

Calculator Screen:

If you want to do your own

calculation, the

Insulation Upgrade Calculator is here...

Gary 2/707