Search

The Renewable Energy site for Do-It-Yourselfers

Advanced Tools for

Making Collector Heat Absorbing Fins

-- aka The Mother of All

Collector Fin Presses

While these tools are great for improving

speed and accuracy of making the fins, it is also quite feasible to use

these simple tools

if you are only doing a few collectors, and don't have Tom's machine shop at

your disposal.

| |

Update on Tom's Absorber Plates

Tom has decided to make absorber plates from his press available as a

regular product from his UP Truck Center business.

He offers plates to fit 1/2 inch and 5/8 inch copper or PEX pipe.

Fin length can be customized from 24 to 34 inches. He offers a

"standard" fit as well as a 90% wrap fit. The modified vice-grip

that make it easier to clamp the fins tight to the tubes are also

available.

The prices are very reasonable, and I can attest to the fact that the

plate fit is very good. I think this is a very good option for

anyone who does not want to bother with making fins.

All the details on ordering and from Tom... |

The kind of tools that Tom made would be a

great investment for a solar club or association to support collector making

workshops -- dozens of collectors could be turned out by a team of people in

a single workshop at a cost of around $120 per collector -- this would

result in a payback period of about 2 years! -- even less if your

state has an incentive or rebate program.

Thanks very much to Tom for making these

descriptions available!

Groove Forming Press

Here are some pictures of the absorber molds I've made to stamp out the aluminum

on my shop press. I plan on making a 320 Sq' collector array for my home this

summer, several of these

pool

heaters, and also will need

diffuser panels in

the house. In addition, several guys I'm working with are designing systems as

well.

I started working with my new

absorber material recently. I ordered a 3,000' coil of 8" x .018 "1100" grade

aluminum. This is supposedly more conductive and malleable than the "6061" grade

I believe the soffit aluminum is made with. It bends really nice, yet holds

shape well too. I've enclosed a few pictures I've taken of the absorber and some

more tooling. With a cost per foot on the soffit running about $.62 a

foot, the coil will get the absorber cost down around $.42 a foot, and will only

need to be cut to length.

The press is a lot easier on my body,

not to mention I can press out the panels in about 1/4 the time. I've quoted a

coil of .018" aluminum, 8" wide and 3000' long.

|

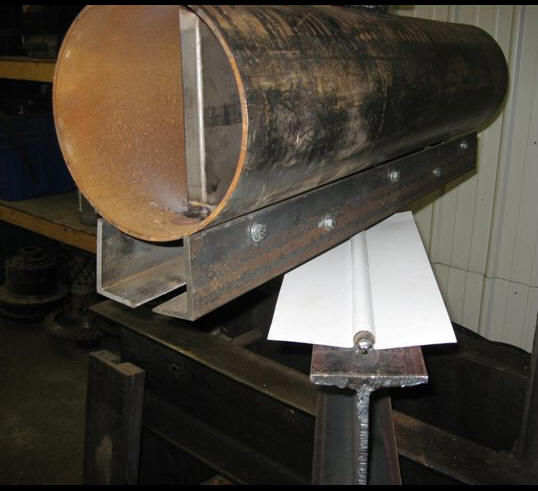

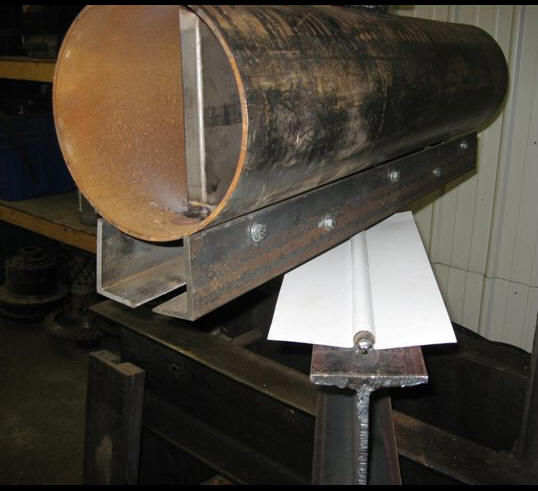

This is the basic groove making tool.

It goes in the press shown in the picture below.

|

|

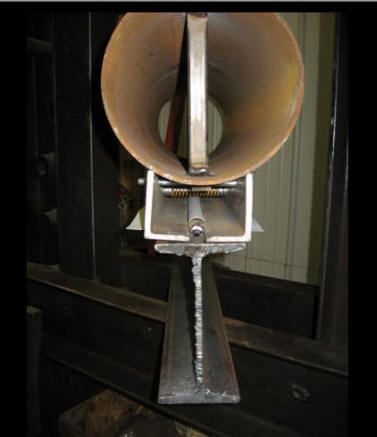

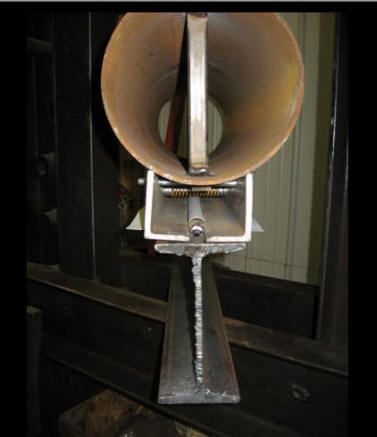

The tool used as the 2nd step in forming

the fin so that it wraps tightly around almost the full diameter

of the copper tube. |

Another view. |

The pressing tools were modified many times to get the version that

works so nicely now. I believe the first molds are pretty self explanatory, and

get the initial shape to the aluminum. The second tool took some time to get

right. I started with three hinges welded to each angle iron and found the press

was stretching the hinges apart. I was also using a flat plate on top of the

angles, but this caused a "scuffing action" as the top of the angles wanted to

move out, and the bottom of the angles pressed the aluminum under the round rod.

I had some pipe left over from the wind turbine tower, and saw it would create a

nice transition area that would naturally push the top of the angles down and

outward at the same time (the bottom of the hinges press in an inward direction

creating the "wrap effect" I'm getting on the absorber). The "hinge point" to

the angles are two bolts in the center of the angles. They have springs on them

to force the lower part of the angles outward at the beginning of the procedure

to clear the widest part of the 3/4" rod (and aluminum absorber). The bolts at

the top of the tool are running through a channel of 1/8" x 1" strap tacked to

the pipe which suspends the angles to the pipe (and ultimately to the top of the

press). As the tool encounters resistance, the top of the angles start to

spread, hinging the bottom of the angles inward. I can run 2 absorbers a minute

through the first tool and 3-4 absorbers a minute through the second tool ( I

can do enough absorbers for 4 panels in a little over an hour).

Fin Installation Clamps

The picture below shows two of the clamps Tom made to hold the fin tightly

against the tubing while the fin is being secured. The tighter the fin

fits over the tube, the better the thermal connection between the fin and

tube, and the better the performance of the collector -- very nice!

A couple of Vice Grip tools I made to get a better "squeeze" on

the absorber before installing my screws.

Aluminum Dispensing Roll and Shear

The picture shows the stand and "shear" I made to store, roll out, and cut

the absorber material. I looked for an old heavy duty paper cutter, but couldn't

find one. Fabricating a shear seemed like the best option. The cutting edge is a

piece from an edge for a big steel shear that a friend of mine had purchased

"new" at an auction but it wouldn't fit his machine. I cut out 75 absorber

blanks (enough for 3 collectors) in about 5 minutes on this shear.

Finished Fins

Some pictures of the finished product.

A stack of the new material after pressing on my molds

Note how well formed Tom's fins are, and how the groove wraps nearly the full

circumference of the tube -- this is the key to good thermal contact between the

tube and the fin, which results in a high efficiency absorber.

| |

A collector completed with the new

absorber material |

Collectors on trailers for

school demonstration |

|

Tom

March 28, 2009, and May 13, 2009

Tom will answer email questions --

you can reach him at: toms1 AT chartermi DOT net (replace At with @, DOT with

.)

Tom's Other Projects

Tom has sent in

several great renewable energy projects ...

Gary March 31, 2009, Added

clamps and shear May 13, 2009