Search

The Renewable Energy site for Do-It-Yourselfers

Copper/Aluminum

Prototype Performance

Side-by-side

test of Copper/Aluminum collector and PEX/Aluminum collector

This shows the performance of both

the Cu/Al 32 sqft prototype collector and the PEX/Al 32 sqft collector.

|

Cu/Al collector to left, and PEX/Al

collector to right. |

Each collector heats 5 gallons of

water in a separate red

insulated ice chest.

The submersible pumps are located

in the ice chests.

Click pictures for full size |

In this test, the Copper tube with Aluminum Fin 32

sqft prototype is run side by side with the

PEX tube with Aluminum Fin prototype

of the same size. Both collectors are oriented the same way. Both

are supplied water from identical 5 gallon insulated ice chests via identical

submersible pumps -- this is like the

small panel test, only with

big panels.

Tambient is about 75F, flow rate is about 3 gpm, and water in each reservoir is

5 gallons (full).

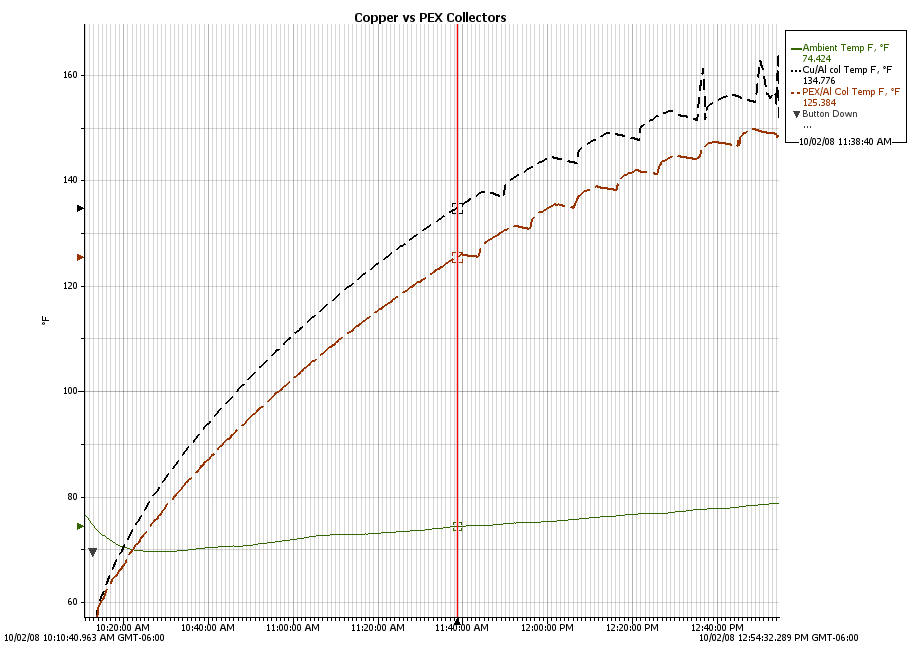

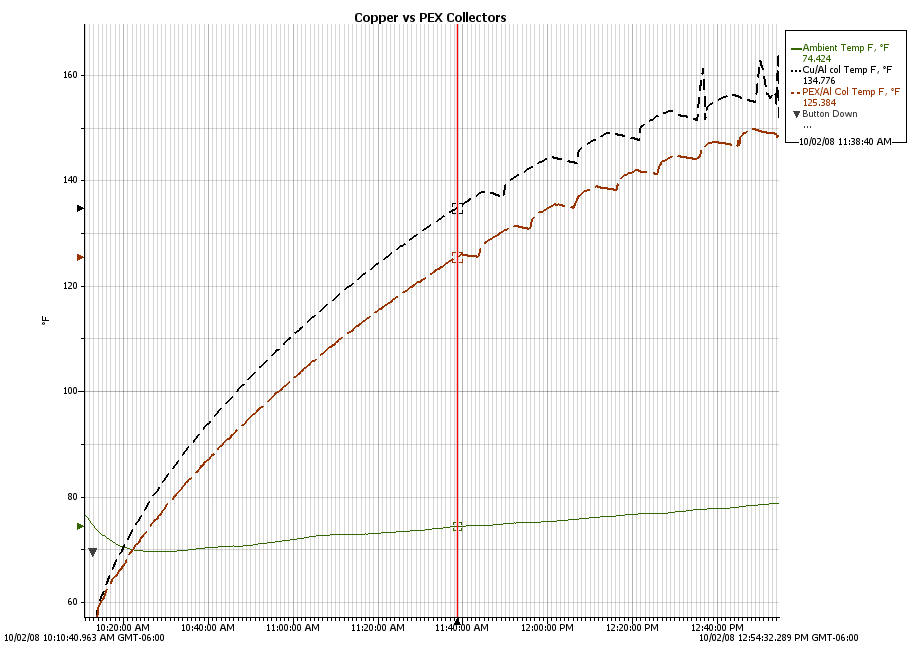

This plot shows the temperature of

reservoirs for each collector.

The black dashed line is the

copper/aluminum collector reservoir temperature (F).

The dark orange long dash line is the

PEX/aluminum collector reservoir temperature (F).

The dips in each line above about

125F are the pumps shutting off for a while because their thermal protection is

tripping, so the part of the plot above these dips should be used with caution.

Both reservoirs start at 60F.

When the Cu/Al has reached 134.7F, the PEX/Al is at 125.4F, so the warm-up for

the Cu/Al is 74.7F, and the warm-up for the PEX/Al is 65.4F. So, the

Cu/Al adds about 14% more heat to the reservoir over the first 1.3 hours.

This agrees well with the results from the

small panel tests.

Both collectors are still increasing

the temperatures of their reservoirs up in the 150F area in spite of the pumps

cutting out at times.

I believe that for all practical

purposes, the Cu/Al collector can be considered equivalent to what a commercial

collector would do (see the small

panel tests for the reasoning behind this), so you can also look at the plot

as a pretty good comparison of how the PEX collector would do relative to a

commercial collector.

The heating rate in this test works

out to about 1 showers worth of hot water per hour for a 32 sqft collector (full

sun).

Copper/aluminum collector alone hooked to 38 gallon

reservoir

In these two tests, the Cu/Al collector is connected to 38 gallons of water in a

galvanized steel stock tank just behind the collector. The stock tank ins

insulated fairly well with 2 inch polyiso insulation board.

Picture shows the 38 gallon tank with its insulation panels installed.

Day 1:

A small submersible pump that provides about 1.4 gpm flow

was used. The pump is being powered by a 15 watt PV panel for this test.

The plot below shows the temperature of the tank over the course of the day.

I was not able to get started at first sun, so this is a partial day.

Ambient temperature was in the low

70's.

The collector heats the water in the

tank from about 55F up to about 116F.

The rate of temperature change

between 1pm and 2pm when the tank is in the 95F area is about 13 F per hour --

this seems like a good rate for the most important part of the storage tank heat

recovery for a solar water heater.

The interruption in heating rate

starting at about 11:30 am and going until about 12:45 pm was caused by a pump

problem. It appears that without that problem the tank would have gained

about another 5F by the end of the day.

Day 2:

This is the day after the test above,

and starts with the tank partially heated (as it would usually be in a real

system).

The tank starts at 92F, and makes its

way up to 140F.

The leveling off at 140F is due to

time of day rather and increasing afternoon incidence angle.

Same pump and flow rate as Day 1.

My yard is beginning to look like a northern branch of the SRCC.

Far left in background are the garage/shop solar heater doors, then the

copper/aluminum collector

prototype (on rack), then the PEX/aluminum collector prototype (on rack), and in

the right background is the

PEX/aluminum collector for our actual solar hot water system.

I have a very patient wife.

Gary September 29, 2008, September

30, 2008, October 2, 2008