How to Get Even Flow in Downspout Collectors?

I built a simple prototype of the

gutter

downspout collector as shown here..

The air inlet and outlet areas look like this:

Back to the Solar Air Heating Collector test program

home..

Back to the Solar Air Heating Collector test program

home..

Target Flow Characteristics

The aim is to achieve about 3 cfm per sqft of collector area, or 90 cfm

for the full collector. The idea being that 3 cfm per sf should give

good efficiency.

With this flow rate, the flow per downspout is 6.9 cfm, and the downspout

velocity is about 170 fpm for the 3 inch by 2 inch downspouts.

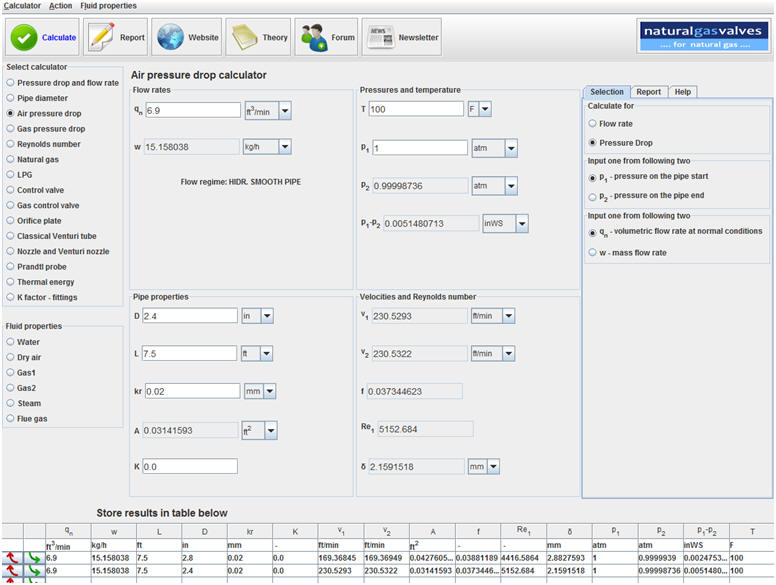

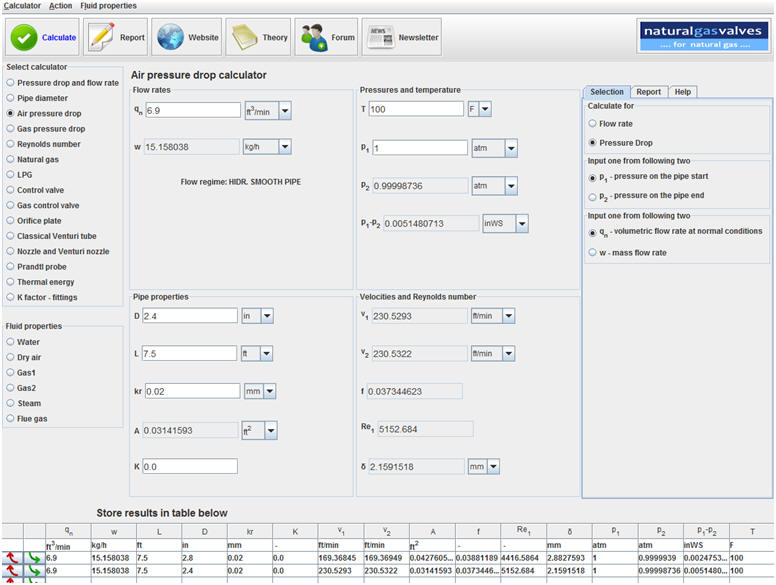

At this flow rate, the calculated pressure drop in each downspout is only

about 0.005 inches of water -- this is not counting pressure losses at the

inlet and outlet of the downspout and is using a hydraulic radius of 2.4

inches. So, quite a small pressure drop.

The Reynolds number for the flow in the downspout is about 5000 -- so,

the downspout flow should be turbulent and well mixed.

This is mostly from this calculator:

http://www.pipeflowcalculations.com

Manifolds -- a Compromise

In thinking about how to design the inlet and outlet manifolds, the first

thought was to design them as plenums with the inlet at the lower left and

outlet at the upper right of the collector. For a good plenum, you

would want the plenum velocities to be relatively low and the pressure in

the plenum to be high relative the pressure drop in the runners (downspouts

in our case) -- this way the plenum operates close to the ideal of a

constant pressure source for each of the downspouts. But,

the manifolds get pretty large if you do this -- the total area of all the

downspouts is 13 * 6 = 78 sqinches. If you made the plenum such

that its inlet velocity was equal to a downspout velocity (170 fpm), then

the plenum would end up being 4.5 inches deep (the depth of the collector)

and 17.3 inches tall -- so you would end of with 34 inches of plenum covers

in the 94 inch tall collector. This seems excessive given that the

area occupied by the plenum covers is not going to be as efficient a solar

collector as the downspout area.

So, I ended up putting the inlet ducts into the middle of the collector

manifolds (for flow in both directions), and cut the area back from 78

sqinches to about 30 sqinches. This makes for a manifold that is 4.5

inches deep by about by 6.5 inches tall. This gives a flow near the

center of the manifold of about 90/2 = 45 cfm and a velocity of (45

cfm)/(30/144 sf) = 216 fpm, or somewhat higher than the downspout velocity.

This is not based on any science -- just a guess.

The top (glazing side) cover on the manifolds is a sheet of black painted

aluminum, so the plenum areas are still somewhat effective as solar

collection area.

Checking the Evenness of Airflow Distribution Across the Downspouts

To see how good a job the inlet manifold did of spreading the air flow

evenly to each duct, I left the cover plate off the outlet manifold, hooked

up a blower to the inlet manifold, and measured the flow velocities in each

of the downspout tubes at the outlet manifold end. I tried this

with the blower hooked up to blow into the collector and with the fan turned

around to suck air out of the collector.

Measuring the flow for each downspout outlet.

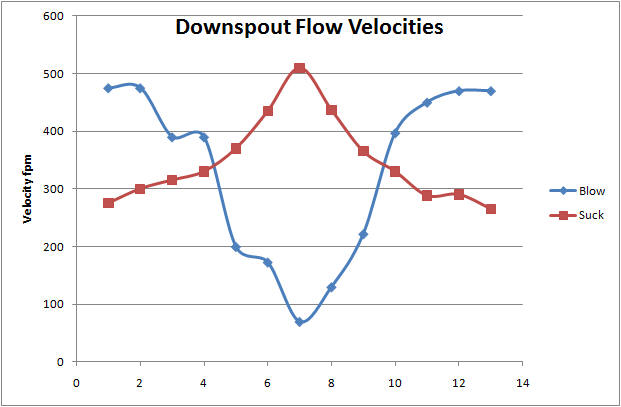

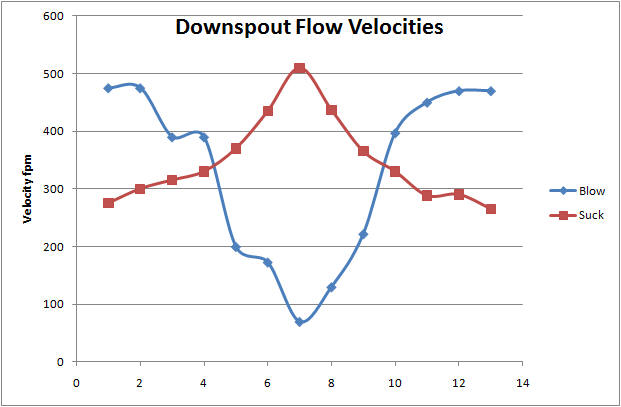

The plot below shows the results.

Downspouts 1 and 13 are the left right end downspouts, and downspout 7 is in

the middle right where the inlet air comes in.

So, in the blow case, the center downspouts get very little flow and the

outer downspouts get quite a bit of flow. This was a bit of a surprise

given that the center downspouts are right next to the inlet duct.

In the suck case, the opposite happens -- the center downspouts get more

flow than the outside downspouts. Also puzzling?

Thinking that maybe having the outlet manifold cover off was effecting

the flow distribution, I put the outlet cover on, and measured the flow in

three of the downspouts by cutting holes in them about half way up and

inserting the Kestrel wind meter in the holes. The holes were taped

over when not taking velocity measurements.

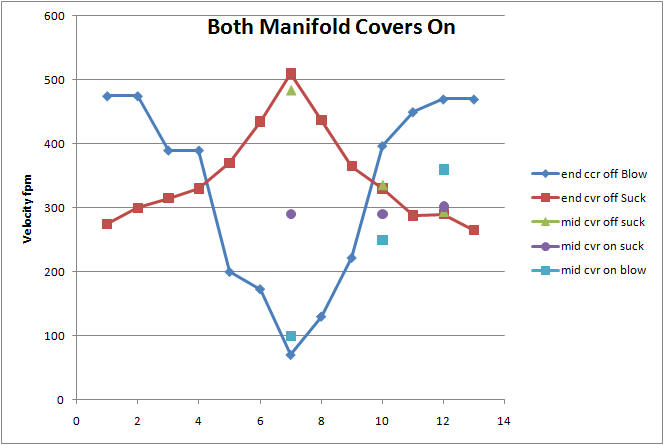

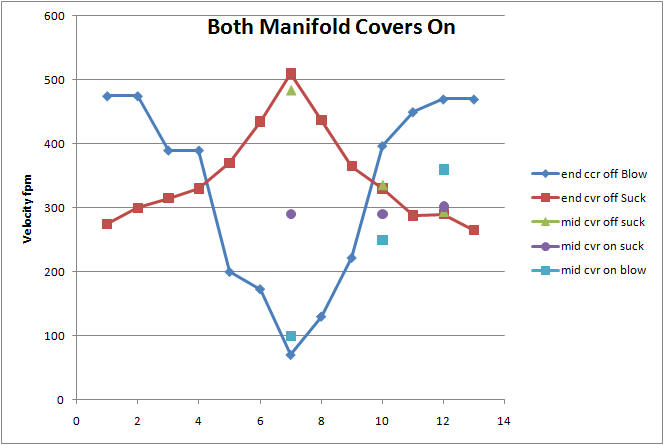

The plot below is the result.

This plot shows the same runs as are on the other plot PLUS three new

runs -- for the new runs, the velocity measurements were taken by cutting

holes in three of the downspouts (numbers 12, 10 and 7) half way up the

downspout, and using the Kestrel wind meter inserted in the holes. The

holes are closed off with tape when not taking reading.

Green triangle -- sucking, inlet manifold cover on,

exit manifold cover off -- ie same as red square except measured at mid

downspout.

Purple circle -- sucking, inlet and exit manifold

covers on -- ie same as Green Triangle, but exit cover on.

Aqua square -- blowing, inlet and exit manifold

covers on -- ie same as Blue Diamond, but with exit cover on.

So, for the sucking case, putting the exit manifold cover on makes the

downspout velocity quite even all the way across -- just what is wanted.

For the blowing case, putting the exit manifold cover on helps to even

out the downspout velocities somewhat, but they are still much lower near

the center. Even though its better, there is still more than a 3 to 1

difference between lowest and highest.

The green triangle is the same as the red square (exit cover off) except

that the velocities are measured mid duct rather than at the end. This

was done as a sort of control, and they track very well.

I'll probably go ahead and test the collector in its current

configuration, but I'd be very interested in hearing if anyone has any good

explanations for what's going on with the flow distribution, or ideas on how

do design a manifold system with some assurance that it will distribute

flows to each downspout evenly.

Gary...

For people with finished downspout collectors who want to check on flow

distribution, taking the glazing off and measuring the outside temperature

of the downspouts with an IR temperature gun would probably give a good

indication. Please let me know what the result is if you do this.

Gary May 3, 2011